In recent years, carbon fiber wheels have gained traction in the automotive world, especially among truck enthusiasts seeking to enhance both performance and aesthetics. Known for their exceptional strength-to-weight ratio, carbon fiber wheels offer significant benefits over traditional materials, making them a popular choice for high-performance vehicles.

However, this rising trend brings forth a critical question for owners: when damaged, should a carbon fiber wheel be repaired or replaced? The answer is not always straightforward. While some cosmetic issues may be salvageable, structural damage can dramatically alter the wheel’s integrity, and understanding the nuances of repair versus replacement is essential.

In this article, we will explore the implications of choosing carbon fiber wheels for your truck, the costs associated with repairs, and the signs that dictate when it’s time to let go and invest in a new set. Join us as we navigate the complexities surrounding carbon fiber wheel repairs and what they mean for your vehicle’s performance and safety.

Carbon fiber wheels mounted on a sleek truck, showcasing their design and aesthetic appeal.

An image showing the process of applying epoxy to a damaged carbon fiber wheel, emphasizing the repair process.

Types of Damage to Carbon Fiber Wheels

Carbon fiber wheels offer significant performance advantages due to their lightweight and stiffness. However, they are susceptible to specific types of damage that can adversely affect both performance and safety.

Types of Damage

- Impact Damage:

- Surface Scratches and Chips: Minor abrasions may not immediately compromise structural integrity but can expose the material to environmental degradation.

- Deep Gouges: Penetrations into the carbon fiber weave can create stress points, potentially leading to crack formation under normal loads. Automodexpress

- Catastrophic Structural Failure: Severe impacts, such as hitting a curb at high speed, can cause immediate and complete wheel failure. Automodexpress

- Heat-Related Damage:

- Resin Degradation: Extended braking, especially during long descents, can raise rim temperatures above 150°C (300°F), potentially softening the resin and leading to delamination. Automodexpress

- Thermal Cycling Fatigue: Repeated heating and cooling cycles can cause micro-cracks and residual stress buildup, weakening the wheel over time. Superteamwheels

- Environmental Factors:

- Moisture Ingress: Exposure to moisture can degrade the mechanical properties of carbon fiber, particularly at the matrix-fiber interface. Wikipedia

- Cold Weather Effects: In extreme cold, the resin may become less flexible and be more prone to cracking if subjected to impacts. Elite Wheels

Effects on Performance and Safety

- Performance Impacts:

- Damage can lead to reduced stiffness and strength, affecting handling, acceleration, and braking efficiency.

- Heat-induced resin degradation may result in delamination, compromising the wheel’s structural integrity and performance.

- Safety Concerns:

- Cracks or delamination can lead to sudden wheel failure, posing significant safety risks.

- Heat-related failures during prolonged braking can cause the rim to deform or the tire to blow off. Where the Road Forks

Preventive Measures

- Regular Inspections: Check for visible damage such as cracks, chips, or signs of delamination.

- Proper Braking Techniques: Avoid prolonged braking to minimize heat buildup.

- Environmental Protection: Store wheels in controlled environments to prevent moisture ingress and protect against extreme temperatures.

Understanding these damage types and their implications is crucial for maintaining the performance and safety of carbon fiber wheels.

| Type of Repair | Cost Range |

|---|---|

| Basic Cosmetic Repairs | $100 – $250 |

| Structural Repairs | $400 – $800 or more |

| Full Replacement of Wheels | $1500 – $5000 or more |

Repair Process for Cosmetic Damage on Carbon Fiber Wheels

The repair of cosmetic damage to carbon fiber wheels involves restoring appearance while ensuring structural integrity. Below is a concise overview of the typical repair process.

1. Assessment of Damage

The repair process begins with determining if the damage is cosmetic or structural. Cosmetic issues involve mere surface scratches or chips, while structural damage includes cracks or delamination.

2. Surface Preparation

- Cleaning: Thoroughly clean the damaged area to remove dirt and debris.

- Sanding: Lightly sand the area with fine-grit sandpaper to smooth out imperfections without damaging the underlying carbon fibers.

3. Epoxy Application

- Filling Imperfections: Apply high-quality epoxy resin to fill scratches and chips, ensuring durability.

- Curing: Allow the epoxy to cure following manufacturer guidelines for proper hardening.

4. Surface Smoothing

- Sanding Again: After curing, sand the area to create an even finish that integrates with surrounding material.

5. Painting and Finishing

- Priming and Painting: Apply a primer to enhance paint adhesion, followed by matching paint to restore color.

- Clear Coating: Finish with a clear coat for protection and UV resistance.

Cosmetic vs. Structural Integrity in Repairs

The distinction between cosmetic and structural repairs is vital:

- Cosmetic Repairs: Focus on visuals and do not compromise safety if done correctly.

- Structural Repairs: Address integrity issues and require professional assessment to prevent failures.

Consulting experts in carbon fiber wheel repairs ensures optimal results and safety.

Structural Repairs and Considerations for Carbon Fiber Wheels

Repairing structural damage in carbon fiber wheels poses unique challenges and requires specialized techniques to ensure safety and performance standards are maintained. The process begins with a thorough assessment of the damage to determine its nature, whether it is cosmetic or structural. This evaluation is essential as it informs the repair approach and decides if the wheel can be salvaged or should be replaced.

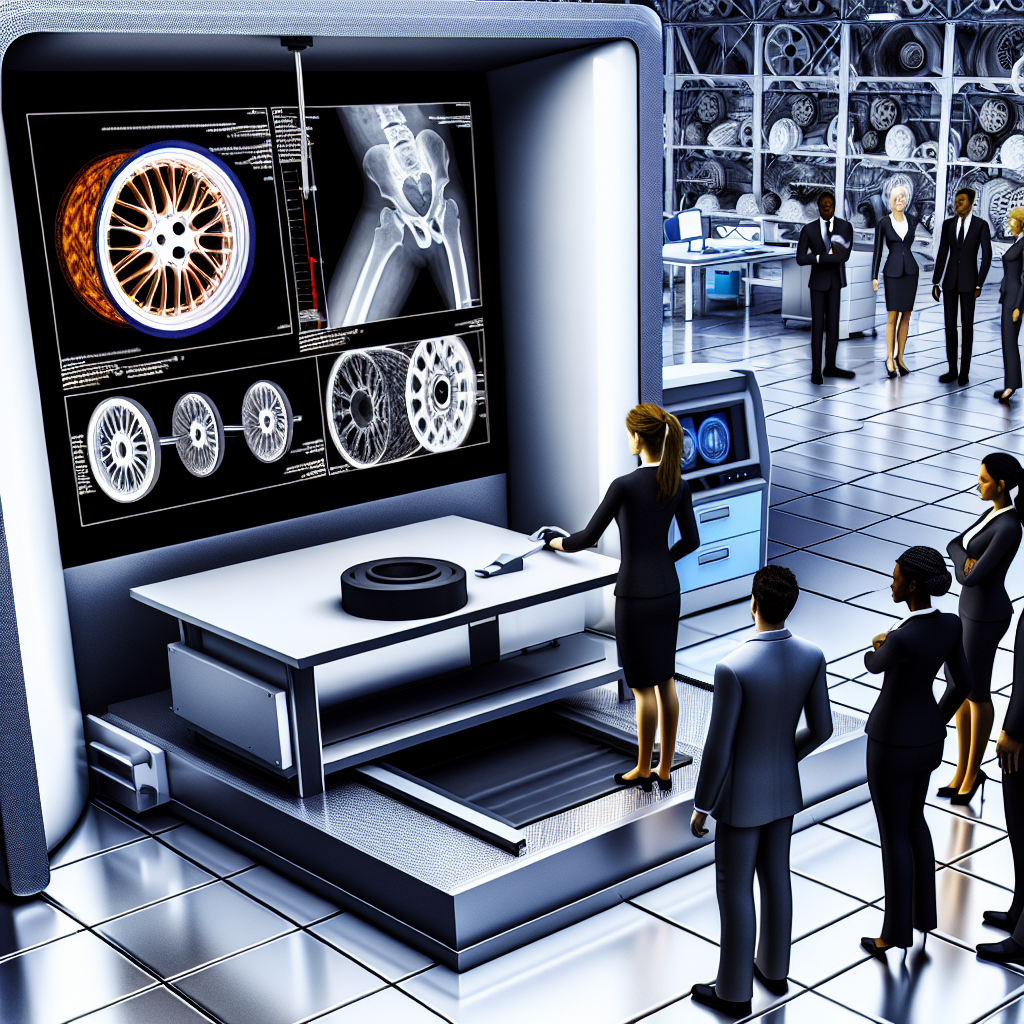

X-Ray Inspections

One of the most effective methods for assessing structural damage is the use of X-ray inspections. This non-destructive testing (NDT) technique provides a detailed view of the internal structure of the wheel, allowing technicians to identify imperfections such as cracks, delamination, and fiber misalignment that may not be visible on the surface. Facilities specializing in carbon fiber components, like Spyder Composites, employ advanced X-ray technology to conduct these inspections, offering a reliable way to ascertain the integrity of carbon fiber wheels before any repair efforts are initiated.

Determining Repairability vs. Replaceability

The decision between repairing or replacing a carbon fiber wheel hinges on several critical factors outlined below:

- Minor Cosmetic Damage: For superficial damage, such as surface scratches or clear coat chipping, repairs can typically be made through techniques like sanding and refinishing without compromising the structural integrity of the wheel. These types of cosmetic fixes are often appropriate for DIY approaches, making them cost-effective options.

- Structural Damage: When cracks penetrate the carbon fiber weave or significant damage occurs, professional assessment becomes necessary. The repair process may involve intricate techniques, including layering new carbon fiber and applying resin to restore strength. However, if extensive delamination or fractures exist, replacement may be the most prudent choice. The risks associated with improper repairs can lead to catastrophic failure, particularly since carbon fiber lacks warning signs and tends to fail suddenly [source].

- Performance and Safety Risks: Ensuring the wheel’s performance and safety is paramount. Repairs that do not fully restore the wheel’s strength pose risks, particularly under load conditions. Given that carbon fiber wheels are designed to endure substantial stresses, compromised areas, if poorly repaired, are prone to failure. Thus, maintaining rigorous standards during repair processes is crucial.

In summary, while minor cosmetic damages to carbon fiber wheels may be repaired effectively, any structural damage should be scrutinized thoroughly through methods like X-ray inspections. Such assessments aid in making informed decisions between repair and replacement, prioritizing safety and performance integrity for truck enthusiasts who depend on these components for optimal driving conditions. By trusting in professional evaluations and skilled repairs, owners can navigate the complexities of carbon fiber wheel maintenance with assurance.

An image showing the X-ray inspection process for assessing structural damage in carbon fiber wheels.

Expert Opinions on Repairing Carbon Fiber Wheels

The allure of carbon fiber wheels lies in their advanced engineering and performance benefits, yet they come with significant risks when repairs are needed. Industry experts and manufacturers provide crucial insights into the complexities of repairing these components, emphasizing safety considerations that every truck owner should know.

Understanding the Risks of Repair

-

Structural Integrity Concerns:

“Carbon fiber loses its structural integrity once damaged. Unlike metal, which can bend and be reshaped, carbon fiber fractures, and any repair risks introducing hidden weaknesses that could lead to catastrophic failure during use.”

-

Manufacturing and Repair Challenges:

“Rims are made in a single, precision mould under high heat and pressure. Repairs lack the original compaction and curing quality, may not replicate the precise fibre orientation, and can introduce stress risers or weak points that compromise safety.”

-

Manufacturer Recommendations:

“Original Equipment Manufacturers such as BMW, Daimler-Chrysler, Ford, GM, Honda, Nissan, Toyota and others have released written statements making their positions known that, other than minor cosmetic refinishing, the repair of damaged rims is not recommended.”

Real-Life Examples Highlighting Emotional Engagement

-

Safety Concerns:

Truck owners often feel a deep emotional bond with their vehicles; one owner shared, “It was heart-wrenching to think that my truck, which has been through so much with me, could fail simply because of a bad repair on a carbon fiber wheel. My family’s safety depends on it.”

-

Extent of Damage:

“Cracks near spoke holes or brake interfaces often cannot be safely repaired. These high-stress areas are crucial for safety, and even a high-end repair might not restore their full structural reliability.” This quote news from industry experts resonates with truck owners, illuminating the importance of understanding when to let go of a damaged wheel, stressing that safety comes first.

-

Professional Insight:

“Even after professional work, you’re relying on advanced inspection methods to say whether it’s safe at triple-digit speeds. Some companies acknowledge this uncertainty, which is why they draw such a hard line between what’s cosmetic and what’s structural.”

In conclusion, while cosmetic damage on carbon fiber wheels can often be repaired safely, structural damage presents serious risks that should not be underestimated. Experts advise that owners prioritize safety and, when in doubt, consider replacement as the more reliable option. Navigating these decisions requires careful attention to guidance from manufacturers and experienced professionals in the field.

Choosing Between Repair and Replacement of Carbon Fiber Wheels

When dealing with damaged carbon fiber wheels, truck owners are often faced with the crucial decision of whether to repair or replace them. The decision hinges on multiple factors, including the type of damage, repair costs, and expert recommendations.

Key Insights

-

Damage Types:

- Cosmetic Damage: This includes minor surface issues such as scratches or curb rash. Repairing this type of damage is generally feasible and cost-effective, with repair costs ranging from $100 to $250 per wheel. Techniques involve sanding, applying epoxy resin, and repainting, which can effectively restore the wheels’ appearance without compromising structural integrity.

- Structural Damage: More severe damage like cracks or delamination alters the wheel’s strength and safety. Structural repairs, required for these types of damage, can be complex and costly, ranging from $400 to $800 or more per wheel. If cracks are located in high-stress areas, like near spoke holes, repairs may not be possible, necessitating replacement, which can range from $1,500 to $5,000 per wheel.

-

Cost Considerations:

Repairing cosmetic issues is typically more affordable and may be a no-brainer for minor damages. However, if repairs approach the cost of replacement, or if structural integrity cannot be assured, opting for new wheels may be safer and more economical.

-

Expert Recommendations:

Experts caution that while cosmetic repairs can often be safely performed, any structural damage needs careful assessment. Industry professionals recommend turning to specialists who can utilize methods like X-ray inspections to evaluate damage accurately. These assessments can determine whether the damage is repairable or if replacement is essential to maintain safety standards.

Various manufacturers advocate for replacement over repair in cases of significant structural compromise, as the risks associated with improperly repaired carbon fiber can lead to catastrophic failures due to the material’s brittle nature.

-

Guidelines for Decision Making:

- Repair: Consider when damage is superficial, and the cost of repair is significantly lower than replacement costs.

- Replacement: Opt when the damage is extensive or in critical areas that affect safety, or when the repair costs approximate those of a new wheel.

Conclusion

In conclusion, while minor cosmetic damages to carbon fiber wheels may be repaired effectively, structural issues carry significant safety risks. Always evaluate the severity and type of damage and consult with professionals to guide your decision. Prioritizing safety through careful assessment can help truck owners maintain performance and ensure safe driving conditions.

Conclusion

Understanding the ins and outs of carbon fiber wheel repairs is essential for truck owners who seek to maintain both the performance and safety of their vehicles. The balance between cost, safety, and performance can be a delicate one. Minor cosmetic damages can often be repaired economically, restoring the wheel’s appearance without adversely affecting its integrity. However, structural damages, which can compromise safety, require careful consideration and typically call for professional assessment.

The importance of professional evaluations cannot be overstated. While some repairs may seem feasible, reliance on expert opinions ensures that decisions are made with the utmost attention to safety and performance standards. Whenever there is doubt about the integrity of a repaired wheel, replacing it can often be the more prudent choice, despite the higher upfront costs.

Ultimately, truck owners are encouraged to adopt best practices for wheel care, including regular inspections, appropriate braking techniques to minimize heat buildup, and knowledge of when professional help is necessary. By being proactive and informed, truck owners can strike the right balance between maintaining their investment in carbon fiber wheels and safeguarding their vehicle’s performance for years to come.

Repair Costs Summary

| Type of Repair | Cost Range |

|---|---|

| Basic Cosmetic Repairs | $100 – $250 |

| Structural Repairs | $400 – $800 or more |

| Full Replacement of Wheels | $1500 – $5000 or more |

By understanding the costs associated with different types of repairs, truck owners can make informed decisions based on their needs. Ensuring regular wheel maintenance and being aware of potential performance upgrades can also help maximize the lifespan of carbon fiber wheels.

Conclusion

Understanding the ins and outs of carbon fiber wheel repairs is essential for truck owners who seek to maintain both the performance and safety of their vehicles. The balance between cost, safety, and performance can be a delicate one. Minor cosmetic damages can often be repaired economically, restoring the wheel’s appearance without adversely affecting its integrity. However, structural damages, which can compromise safety, require careful consideration and typically call for professional assessment.

The importance of professional evaluations cannot be overstated. While some repairs may seem feasible, reliance on expert opinions ensures that decisions are made with the utmost attention to safety and performance standards. Whenever there is doubt about the integrity of a repaired wheel, replacing it can often be the more prudent choice, despite the higher upfront costs. In addition, truck owners should pay attention to wheel maintenance to avoid unnecessary repairs, which can also help control costs. Understanding the implications of performance upgrades can further improve vehicle handling and safety.

Ultimately, truck owners are encouraged to adopt best practices for wheel care, including regular inspections, appropriate braking techniques to minimize heat buildup, and knowledge of when professional help is necessary. By being proactive and informed, truck owners can strike the right balance between maintaining their investment in carbon fiber wheels and safeguarding their vehicle’s performance for years to come.

Repair Process for Cosmetic Damage on Carbon Fiber Wheels

The repair of cosmetic damage to carbon fiber wheels involves restoring appearance while ensuring structural integrity. Below is a concise overview of the typical repair process.

1. Assessment of Damage

The repair process begins with determining if the damage is cosmetic or structural. Cosmetic issues involve mere surface scratches or chips, while structural damage includes cracks or delamination.

2. Surface Preparation

- Cleaning: Thoroughly clean the damaged area to remove dirt and debris.

- Sanding: Lightly sand the area with fine-grit sandpaper to smooth out imperfections without damaging the underlying carbon fibers.

3. Epoxy Application

- Filling Imperfections: Apply high-quality epoxy resin to fill scratches and chips, ensuring durability.

- Curing: Allow the epoxy to cure following manufacturer guidelines for proper hardening.

4. Surface Smoothing

- Sanding Again: After curing, sand the area to create an even finish that integrates with surrounding material.

5. Painting and Finishing

- Priming and Painting: Apply a primer to enhance paint adhesion, followed by matching paint to restore color.

- Clear Coating: Finish with a clear coat for protection and UV resistance.

Cosmetic vs. Structural Integrity in Repairs

The distinction between cosmetic and structural repairs is vital:

- Cosmetic Repairs: Focus on visuals and do not compromise safety if done correctly.

- Structural Repairs: Address integrity issues and require professional assessment to prevent failures.

Consulting experts in carbon fiber wheel repairs ensures optimal results and safety.

As we’ve seen, cosmetic repairs can significantly improve the visual appeal of carbon fiber wheels, providing a temporary solution that enhances the overall aesthetics. However, understanding the limitations of these repairs helps navigate the more intricate world of structural damage, which, if neglected, poses a substantial risk of failure. The journey from restoring a wheel’s surface to ensuring its inner strength underscores the importance of expertise in both repair areas, guiding truck owners to make informed decisions about their carbon fiber wheels.

Structural Repairs and Considerations for Carbon Fiber Wheels

Repairing structural damage in carbon fiber wheels poses unique challenges and requires specialized techniques to ensure safety and performance standards are maintained. The process begins with a thorough assessment of the damage to determine its nature, whether it is cosmetic or structural. This evaluation is essential as it informs the repair approach and decides if the wheel can be salvaged or should be replaced.

X-Ray Inspections

One of the most effective methods for assessing structural damage is the use of X-ray inspections. This non-destructive testing (NDT) technique provides a detailed view of the internal structure of the wheel, allowing technicians to identify imperfections such as cracks, delamination, and fiber misalignment that may not be visible on the surface. Facilities specializing in carbon fiber components, like Spyder Composites, employ advanced X-ray technology to conduct these inspections, offering a reliable way to ascertain the integrity of carbon fiber wheels before any repair efforts are initiated.

Determining Repairability vs. Replaceability

The decision between repairing or replacing a carbon fiber wheel hinges on several critical factors outlined below:

- Minor Cosmetic Damage: For superficial damage, such as surface scratches or clear coat chipping, repairs can typically be made through techniques like sanding and refinishing without compromising the structural integrity of the wheel. These types of cosmetic fixes are often appropriate for DIY approaches, making them cost-effective options.

- Structural Damage: When cracks penetrate the carbon fiber weave or significant damage occurs, professional assessment becomes necessary. The repair process may involve intricate techniques, including layering new carbon fiber and applying resin to restore strength. However, if extensive delamination or fractures exist, replacement may be the most prudent choice. The risks associated with improper repairs can lead to catastrophic failure, particularly since carbon fiber lacks warning signs and tends to fail suddenly (source).

- Performance and Safety Risks: Ensuring the wheel’s performance and safety is paramount. Repairs that do not fully restore the wheel’s strength pose risks, particularly under load conditions. Given that carbon fiber wheels are designed to endure substantial stresses, compromised areas, if poorly repaired, are prone to failure. Thus, maintaining rigorous standards during repair processes is crucial.

In summary, while minor cosmetic damages to carbon fiber wheels may be repaired effectively, any structural damage should be scrutinized thoroughly through methods like X-ray inspections. Such assessments aid in making informed decisions between repair and replacement, prioritizing safety and performance integrity for truck enthusiasts who depend on these components for optimal driving conditions. By trusting in professional evaluations and skilled repairs, owners can navigate the complexities of carbon fiber wheel maintenance with assurance.