The Importance of Proper Wheel Torquing

Imagine cruising down the highway, the wind in your hair, when suddenly you hear a violent noise followed by the horrifying realization that your tire has come loose. This near-miss could have not only jeopardized your life but also the safety of others on the road. How often do we overlook the simple yet vital task of properly torquing our wheels?

Proper wheel torquing isn’t just about achieving a technical specification; it plays a direct role in your vehicle’s safety and is a crucial part of wheel maintenance best practices. The connection between wheel torque specifications and vehicle performance is a delicate balance that can lead to catastrophic failures if disturbed.

As we delve deeper into ensuring truck safety through proper lug nut torque checks, understanding the significance of correct torque values could mean the difference between a smooth ride and a potential disaster. Let’s explore the essentials of wheel torquing, safety inspections, and why paying attention to the finer details could save lives.

Consequences of Improper Torque

Improper wheel torque can lead to dangerous situations that affect vehicle safety and performance. Here are key consequences of improper torque:

Over-Tightening:

- Fastener Breakage: Applying too much torque can stretch wheel studs and cause them to break. This weakens the wheel assembly and raises the risk of the wheel coming off. A report from Fine Power Tools highlights this issue.

- Brake Component Damage: Over-tightening may warp brake rotors and drums, leading to vibrations when braking. This decreases braking efficiency and can endanger drivers and passengers (Tools Advisers).

- Thread Stripping: Using excessive force can strip threads on lug nuts and wheel studs, which weakens the wheel connection (Tech Me Stuff).

Under-Tightening:

- Wheel Detachment: Not tightening enough may cause lug nuts to loosen over time, leading to severe incidents like wheel separation while driving. Fleet Maintenance identifies this as a major concern (Fleet Maintenance).

- Uneven Load Distribution: Under-torqued lug nuts place uneven stress on wheel components, causing early wear and possible failures (Tech Me Stuff).

Expert Insights:

Yann Pasco, a Global Business Development Manager at Chicago Pneumatic, emphasizes the importance of mechanics in ensuring proper wheel torque:

“Mechanics and garage technicians that change tires are ultimately responsible for ensuring that wheels are tightened correctly.”

This underscores the crucial need to follow manufacturer-specified torque settings for safety and reliability in vehicles. Additionally, consider this warning:

“Knowing the torque spec is only half the job – actually getting it right in practice is where many people screw up.”

User Adoption and Awareness of Wheel Torquing

User awareness of wheel torque specifications among truck drivers appears to be alarmingly low, leading to dangerous situations on the road. During a span from 2000 to 2003, a staggering 83% of wheel separations due to fastener failure occurred shortly after wheels were reinstalled, indicating negligence in following proper torque specs. The National Transportation Safety Board (NTSB) investigated various fatal incidents resulting from wheel detachments, one notable case from 1991 resulting in three deaths when a detached wheel hit a school bus.

The primary drivers of wheel separations include the loss or breakage of wheel fasteners and wheel bearing failures, both often attributed to improper maintenance practices. Additionally, the misuse of impact wrenches can lead to over-torquing, causing wheel stud stretching and system failures. Collectively, these statistics emphasize the critical need for truck drivers to be informed about and adhere to correct wheel torque specifications to enhance safety on the roads.

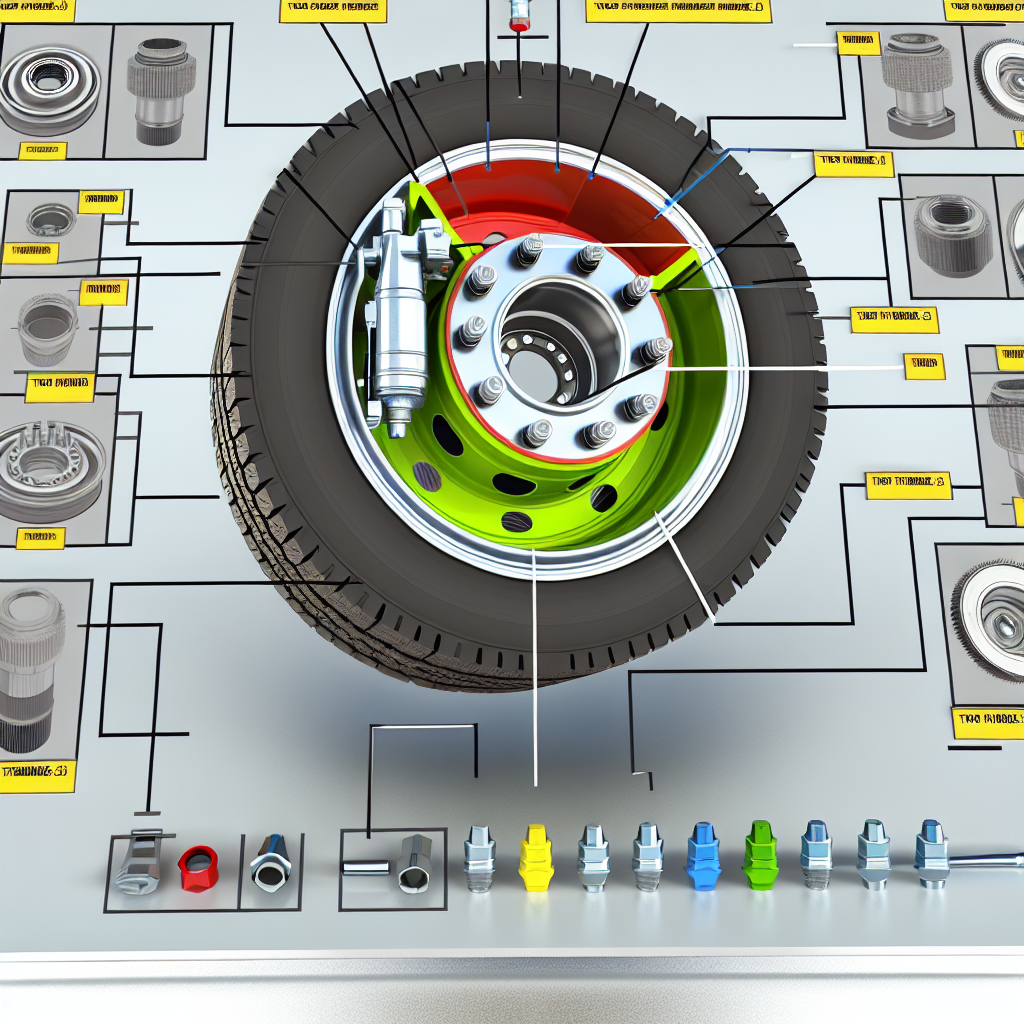

Key Facts About Wheel Torque

- Measurement: Wheel torque is measured in pound-feet, which indicates the amount of rotational force applied to the lug nuts.

- Preventing Wheel Detachment: Proper torque ensures that lug nuts are tight enough to prevent wheels from loosening while driving, significantly reducing the risk of accidents.

- Frequency of Checks: It’s recommended to check the torque after the first 50 to 100 miles after new wheels are installed. Regular maintenance intervals should also include periodic torque checks to ensure safety and compliance with manufacturer specifications.

- Torquing Specifications Vary: Different wheel materials (like alloy and steel) require different torque specifications. For example, alloy wheels often need lower torque to prevent stripping, while steel can handle higher torque.

- Environmental Factors: High humidity, extreme temperatures, and the operating environment can impact the torque applied. Adjustments may be necessary to accommodate these conditions.

- Condition of Wheel Components: Ensure that wheel nuts and studs are clean and free of rust for accurate torque application. Dirty or corroded components can require additional torque for proper installation.

- Adequate Maintenance: Compliance with proper torque specifications promotes fleet safety, avoids fines, and extends the lifespan of vehicle components.

- Expert Guidelines: Consequent tightening should be performed using calibrated torque wrenches to ensure accuracy, following up on manufacturers’ torque recommendations.

For more detailed information on proper wheel torque specifications and their importance, you can refer to these authoritative sources:

Torque Tools Comparison Table

| Torque Tool Type | Pros | Cons |

|---|---|---|

| Manual Torque Wrench |

|

|

| Impact Gun |

|

|

Right Practices for Torquing Wheels

Proper wheel torquing is essential for vehicle safety and performance. Here are best practices for wheel installation, re-torquing, and periodic checks:

-

Clean Mating Surfaces: Before installation, ensure that all contact surfaces—hub, drum, and wheel—are free from rust, dirt, and debris. This promotes proper seating and prevents loosening.

Source -

Use Proper Lubrication: For hub-piloted wheel systems, apply 2-3 drops of SAE 30 weight oil on the outer two threads of the stud and a drop between the nut body and flange. Avoid over-lubrication, as it can affect torque accuracy.

Source -

Follow Manufacturer’s Torque Specifications: Tighten lug nuts to the torque values specified by the vehicle or wheel manufacturer. Over-tightening can damage components, while under-tightening may lead to wheel detachment.

Source -

Adhere to Proper Torque Sequence: Tighten lug nuts in a star or criss-cross pattern to ensure even pressure distribution and proper wheel seating.

Source -

Re-Torque After Initial Installation: After driving 50-100 miles, re-check and re-torque the lug nuts to account for any settling that may occur. This step is crucial to maintain proper clamping force.

Source -

Conduct Regular Torque Checks: Periodically inspect and re-torque lug nuts at intervals recommended by the manufacturer or every 10,000 miles to ensure continued safety and performance.

Source -

Use Calibrated Tools: Employ calibrated torque wrenches to achieve accurate torque settings. Avoid using impact guns for final tightening, as they can lead to over-torquing.

Source -

Monitor for Signs of Loosening: Be vigilant for indicators such as rust lines originating from bolt holes, which can signal low clamping force and potential wheel loosening.

Source

By following these best practices, you can ensure the safety and longevity of your vehicle’s wheels.

Conclusion

In conclusion, properly torquing your wheels is not merely a technical detail—it is a critical safety measure that can prevent potential disasters on the road. Understanding the importance of wheel torque specifications, measured in pound-feet, is essential for every truck driver. The risks associated with improper torque, whether due to over-tightening or under-tightening, can have dire consequences, including wheel detachments and compromised vehicle performance. To stay safe, always re-torque your lug nuts after the first 50 to 100 miles when new wheels are installed and adhere closely to manufacturer specifications.

A personal experience comes to mind involving a friend of mine, Chino Ortiz, who had just installed a set of new alloy wheels on his truck. Excited about the upgrade, he neglected to check the torque specifications after a short drive. A couple of days later, while hauling a heavy load, he heard a loud clunking sound. To his horror, one of the rear wheels had loosened significantly, causing his truck to swerve dangerously. Thankfully, he managed to regain control before any accidents occurred, but it was a close call that left him shaken. This incident not only served as a wake-up call for Chino but also highlighted the importance of proper maintenance to anyone who heard the story.

By implementing best practices for wheel maintenance—including using calibrated torque wrenches—you not only extend the lifespan of your vehicle components but also ensure the safety of yourself and others on the road. So, take the time to check your wheel torque regularly and make it an integral part of your maintenance routine—your safety may depend on it!

Summary of Wheel Torquing Incidents

| Category | Statistic/Insight |

|---|---|

| Wheel Separations (2000-2003) | 83% occurred shortly after wheels were reinstalled. |

| Fatal Incidents Linked to Detachments | Various fatalities investigated by the NTSB, including a 1991 case with 3 fatalities. |

| Common Causes of Wheel Separations | Loss/breakage of fasteners and wheel bearing failures. |

| Impact of Over-Torquing | Can lead to wheel stud stretching and system failures. |

| Awareness Level | Alarmingly low among truck drivers regarding torque specifications. |