In an industry where reliability is paramount, Turnage & Sons stands out not just as a milk hauling company, but as a testament to a family’s unwavering commitment to quality and community. Imagine the rhythmic hum of 29 Peterbilt trucks winding through the countryside, each one meticulously maintained by a team that shares a singular vision: to deliver not just milk, but trust. Since its inception in 2006, Turnage & Sons has faced the storms of Mother Nature and the demands of modern technology, all while nurturing relationships with 33 organic milk producers.

This narrative is more than about trucks and technology; it is about a family dedicated to overcoming challenges through hard work, early troubleshooting, and unwavering support. Join us as we explore how Turnage & Sons melds innovation with tradition, ensuring every drop of milk tells a story of commitment and care.

Turnage & Sons’ Maintenance Practices

Turnage & Sons believes in in-house maintenance, reflecting the family values guiding their operations. They serve 33 organic milk producers with a fleet of 29 custom and legacy Peterbilt trucks. To ensure their trucks are in top condition, Robbie Turnage and his team focus on frequent and thorough maintenance practices.

The company conducts regular inspections and maintenance checks according to a preventive maintenance schedule. This includes routine oil changes, tire rotations, and brake inspections. These practices help catch small issues before they turn into costly repairs. Turnage & Sons’ dedication to maintenance is more than just following procedures; it emphasizes their commitment to the community they serve, building trust with their clients.

Early Troubleshooting Strategies

Proactive troubleshooting is crucial in Turnage & Sons’ operations. By using advanced diagnostic software like Paccar’s Davie Diagnostic Software, they can spot potential problems early. This software helps technicians monitor real-time data from the trucks, flagging any unusual patterns that may suggest future issues. Addressing these early signs can prevent significant downtime, which is essential for their business, where timely milk delivery matters.

Community and Operational Impact

In-house maintenance creates a close-knit work environment. The small team collaborates like a family, fostering strong relationships. Levi Turnage, who is preparing to take over the business, often speaks about the value of this teamwork in keeping the fleet running smoothly and supporting the community. Their choice to maintain operations locally boosts efficiency and strengthens community ties, as every truck on the road signifies reliability and dedication.

In summary, Turnage & Sons emphasizes frequent in-house maintenance and advanced diagnostics to ensure their legacy continues, grounded in family values and commitment to the community. Their practices resonate throughout the local farming community, promoting trust and ensuring the steady delivery of high-quality organic milk to their producers.

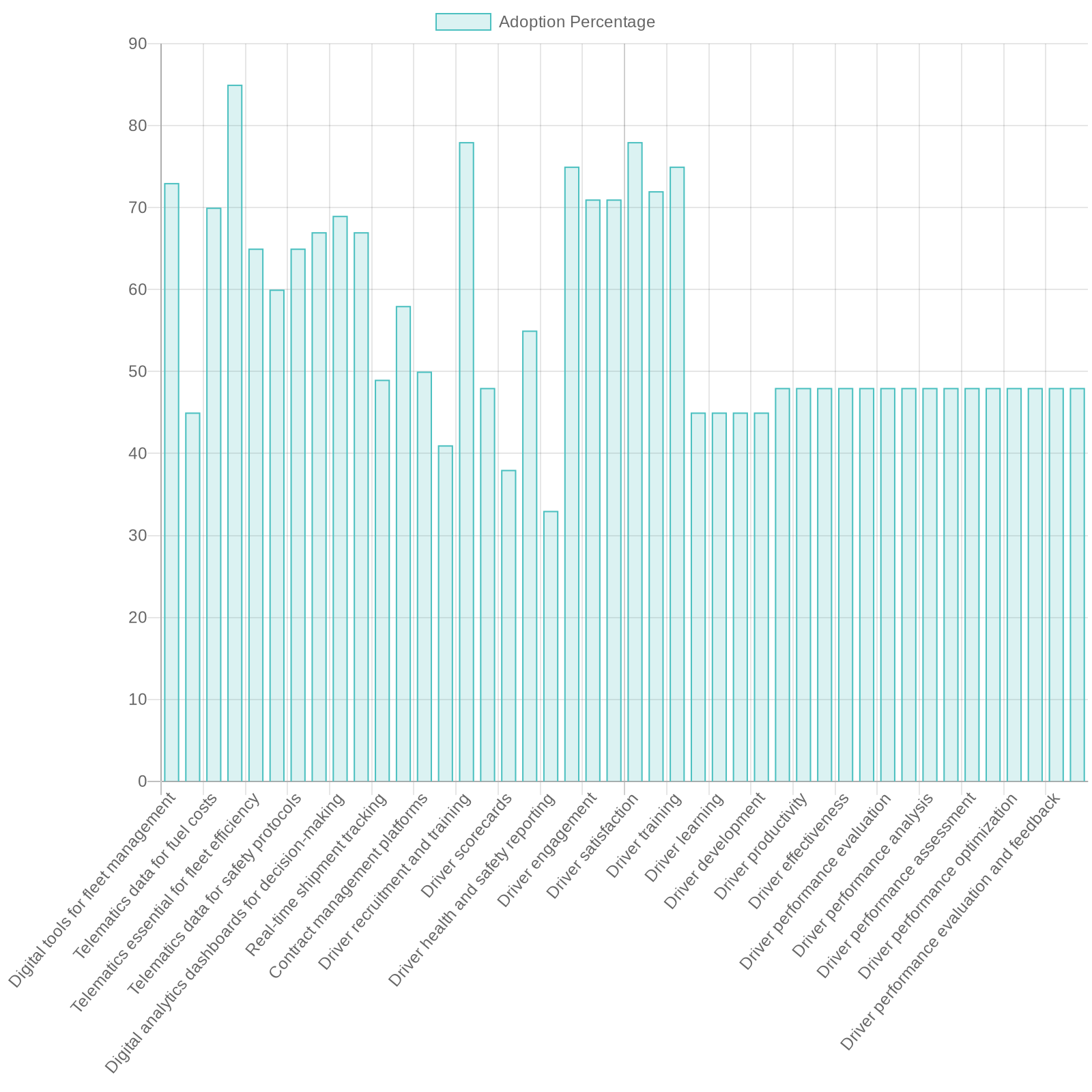

User Adoption of Diagnostic Software in the Trucking Industry

In recent years, the trucking industry has seen a significant shift towards the adoption of diagnostic technologies, with increasing numbers of companies recognizing the value these tools bring to fleet management. According to a report from ZipDo Education, 73% of trucking companies have integrated digital tools into their operations to streamline fleet management, with a notable 45% employing AI-powered predictive maintenance systems.

Trends in Adoption

- Increased Demand for Remote Diagnoses: 98% of fleet maintenance managers utilize telematics for their service and maintenance needs.

- Safety Improvements: 85% of fleet operators reported improvements in their safety metrics through the use of digital safety systems.

Challenges Faced

- Data Security Concerns: Companies face difficulties regarding data security, especially with integration complexities.

- Implementation Hurdles: The transition towards digital systems can complicate existing workflows.

Despite these challenges, the advantages of adopting advanced diagnostic systems, including a 15-20% reduction in maintenance costs and reduced downtime, motivate companies to invest in such technologies. For Turnage & Sons, leveraging Paccar’s Davie Diagnostic Software aligns with these industry trends, allowing them to enhance operational efficiency and safety, thus reinforcing their reliability as partners in the organic milk transportation sector.

This graph showcases key statistics related to the adoption of diagnostic software and digital technologies within the trucking sector, underlining the industry’s movement towards improved fleet management. The metrics indicated reflect the significance of these technologies in enhancing operational efficiency, safety, and reliability for companies like Turnage & Sons.

In-House vs. Outsourced Maintenance Costs

| Aspect | In-House Maintenance | Outsourced Maintenance |

|---|---|---|

| Cost of Labor | Fixed salary costs for technicians | Variable costs based on service contracts |

| Equipment Costs | Investment in tools and equipment | Markup on service fees for equipment |

| Training Costs | Ongoing training for in-house staff | No training costs incurred |

| Overhead Costs | Facility and utility costs | No property overhead |

| Quality of Service | Consistent quality control | Variable based on the contractor |

| Response Time | Immediate access to maintenance needs | Dependent on contractor response |

| Flexibility and Control | Higher flexibility and control over timing | Less control over scheduling |

| Scalability | Limited by available in-house staff | Can scale services easily |

| Long-Term Costs | Potentially lower long-term costs | Often higher over time due to profit margins |

This table outlines a comparison between in-house and outsourced maintenance costs, illustrating financial and service quality considerations crucial for trucking companies, especially in relation to fleet maintenance and operational strategies. Companies like Turnage & Sons should weigh these aspects carefully when deciding on their maintenance strategies, particularly as they relate to sustainable milk hauling and organic dairy transportation.

Visual Representation:

Benefits of Effective Fleet Maintenance

Implementing an effective fleet maintenance program is pivotal, particularly for businesses involved in sustainable milk hauling. Maintaining regular schedules can lead to fewer breakdowns and extended lifespans for vehicles, crucial for companies like Turnage & Sons as they engage in organic dairy transportation. Optimizing fleet management also aligns with growing market demands for sustainability, demonstrating a commitment to eco-friendly practices while maintaining efficiency.

Conclusion

In conclusion, optimizing both in-house and outsourced maintenance strategies can enhance operational efficiency and sustainability within the trucking industry. As companies strive to meet modern business challenges, focusing on reliable fleet maintenance, understanding cost structures, and the impact of sustainability in organic dairy transportation will be essential for continued success and community trust.

The Importance of Community and Family in Business Operations

At Turnage & Sons, community and family are not just values; they’re the pillars upon which the business is built. Robbie Turnage emphasizes that these core principles guide every decision made within the company. He states, “If we’re going to succeed in this business, we have to look out for each other. It’s about relationships, not just transactions.”

This familial approach influences how they interact with their organic milk producers and within their team. With a fleet of 29 trucks, Turnage & Sons not only aims to deliver milk but also to contribute to a thriving community. They believe that their commitment relies heavily on understanding the unique challenges faced by local farmers and working collaboratively to support them. Robbie often says, “Every truck on the road is a reflection of our commitment to the community we serve. It’s about trust.”

The philosophy extends to the operational environment as well. By fostering a workplace culture that mirrors a family setting, the team at Turnage & Sons can collaborate effectively. Robbie’s son, Levi Turnage, who is preparing to carry on the family legacy, echoes this sentiment: “I told Levi when he takes over if he gets a wild hair, ‘I got your back.’ It’s important to me that he knows he has support as he steps into this role.”

Their deep ties to the community can be seen in their involvement with local events and support for community initiatives. In an industry where reliability is crucial, Turnage & Sons stands out not only for their operational strategies but for their unwavering dedication to family values and community commitment. This unique focus shapes a business strategy that prioritizes long-term relationships over short-term gains.

Conclusion

In conclusion, Turnage & Sons exemplifies the profound impact that a strong commitment to in-house maintenance and the adoption of advanced diagnostic technology can have on fleet operations and community relations. By prioritizing frequent maintenance of their fleet of Peterbilt trucks, they ensure not only operational efficiency but also the reliability that is critical in the milk-hauling industry. This approach minimizes downtime, allowing them to remain dependable partners to the 33 organic milk producers they serve.

Moreover, their family-oriented narrative underscores the belief that strong community ties drive their success. Robbie and Levi Turnage embody this philosophy, noting that their operations are rooted in trust and relationships rather than mere transactions. Every maintenance effort not only reflects the company’s dedication to their trucks but also to the farmers who rely on them for timely deliveries. By fostering a tight-knit operational environment and prioritizing local engagement, Turnage & Sons reinforces its role as a dedicated community partner.

Ultimately, the synthesis of technical prowess and a profound commitment to family values positions Turnage & Sons as a leader in the industry. The strategies they employ not only enhance their business outcomes but also cultivate lasting relationships, ensuring that their legacy endures within the community for generations to come.

Operational Strategies and Community Initiatives

At Turnage & Sons, operational excellence is woven into the very fabric of their community-centric approach. By nurturing close relationships with the 33 organic milk producers they serve, the company prioritizes personalized customer service to cater to unique needs. Their commitment is reflected in their responsive operations, which ensure the fleet remains accessible at all hours, handling urgent situations promptly.

Family involvement is paramount, with multiple generations engaged in day-to-day operations, fostering a culture of trust and reliability among employees and clients alike. Moreover, Turnage & Sons embraces innovative technologies, such as advanced route optimization software, to enhance logistics efficiency, reducing costs while maintaining the highest quality of service. These practices not only solidify their position as a dependable partner but also strengthen the bonds within their local community, ensuring that every delivery resonates with their dedication to shared success and sustainability.