Repairing a broken truck frame is essential for maintaining vehicle integrity and safety, especially for fleet managers and operators in the construction and logistics sectors. A damaged frame can lead to safety hazards, operational inefficiencies, and increased maintenance costs. This article presents a detailed examination of the assessment, diagnosis, repair methods, and verification processes associated with truck frame repairs. Each chapter will delve into specific aspects, from initial assessment techniques to extensive repairs and post-repair validation, ensuring that you can navigate the complexities of truck frame restoration with confidence.

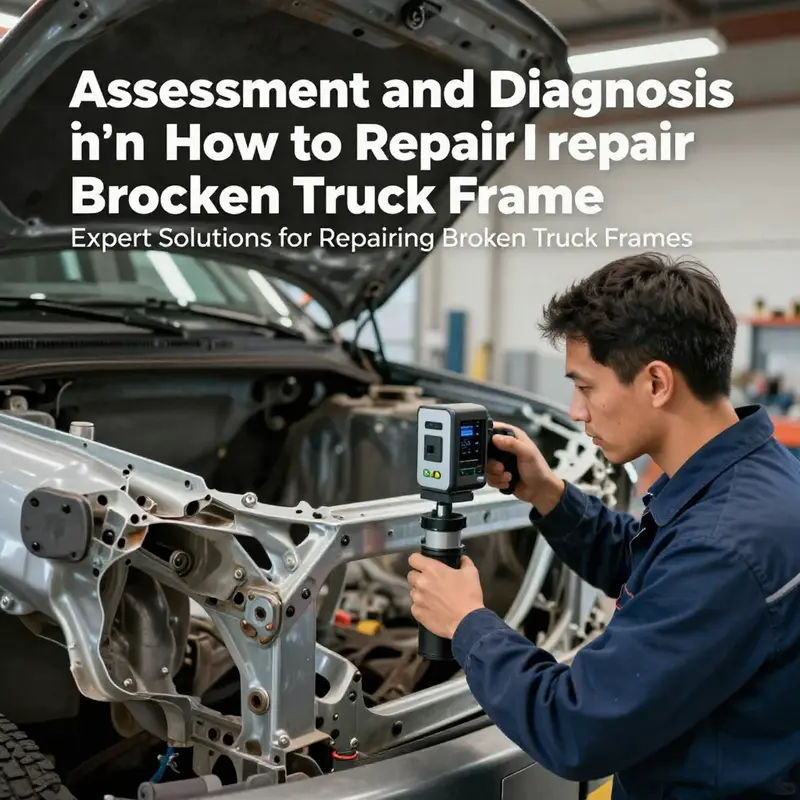

Reading the Frame: The Precision of Assessment and Diagnosis in Repairing a Broken Truck Frame

The assessment phase of repairing a broken truck frame is not a preliminary step; it is the very compass by which every subsequent decision must be guided. In the world of heavy vehicles, where a single misstep can translate into lost cargo, damaged infrastructure, or worse, a life-threatening failure on the road, the value of a meticulous diagnosis cannot be overstated. The frame is the skeleton of the machine, the rigid backbone that carries loads, anchors suspension and steering, and shapes how the truck behaves under every road condition. When this backbone is bent, cracked, or distorted, every other system reacts differently, often in ways that are hard to predict without precise measurement and informed interpretation. The goal of assessment, then, is to translate visible signs into a trustworthy map of structural truth. This map guides all repair work and determines whether the frame can be saved, altered, or must be replaced entirely to restore original performance and safety margins.

The first impression matters, but it is only the starting point. A thorough visual inspection looks for cracks that creep along weld lines, fractures that reveal themselves at the end of rails with fatigue, and distortions that bend the geometry of the chassis. Yet eyes can deceive, especially under the dusty veneer of a used vehicle. That is why professional shops rely on advanced diagnostic tools that quantify what the eye cannot accurately gauge. Computerized three-dimensional body measurement systems scan the entire frame and compare it against the manufacturer’s original specifications. The data they generate illuminate deviations in wheelbase, track width, and diagonal measurements—dimensions that, when skewed even slightly, can cascade into misalignment of the suspension, uneven tire wear, and unpredictable handling. In practice, this means a frame alignment rack or a 3D laser system becomes as essential as a torque wrench or a welder. The measurements are not merely numbers; they are a narrative of the frame’s history and its current state, a language that technicians translate into actionable repair steps.

Beyond the geometry, the diagnostic process must identify the damage type with clarity. A crack might indicate a material flaw or a local overload; a fracture could reveal accumulative fatigue and cycles of stress; a twist or general distortion points to more global deformation that reverberates across the rails and crossmembers. Each category demands a different repair strategy, and the choice hinges on accuracy. The assessment also extends to assessing the metal’s condition itself: corrosion that eats at the rails, weld failures that weaken joints, or softened zones that betray heat exposure or repeated bending. Such findings alter the repair plan as surely as a map alters a route. The careful diagnostician keeps a record of every observable defect, every measurement, and every anomaly in material behavior. This record becomes part of the vehicle’s history and a crucial reference when the vehicle returns to service after repair, whether for regulatory inspection or future resale.

The vehicle’s history compounds the diagnostic challenge. A frame that has already endured a prior collision or a series of improper repairs carries hidden risks. Even if the present damage appears localized, preexisting weaknesses can shift the safety margins when loads are reintroduced or when the vehicle faces a demanding road profile. Qualified technicians treat history as a probabilistic factor, not a certainty. They review prior work, inspect previous welds for signs of fatigue, and verify that past fixes did not compromise contours that influence alignment. The goal is not to rewrite the past but to ensure the present repair does not become the seed of future problems. In this context, a rigorous assessment becomes a rigorous risk management exercise. The diagnostic team must be confident not only in identifying what is broken but in understanding what else might be compromised and how that impacts the long-term integrity of the frame.

All of this culminates in a repair plan that is as evidence-based as a clinical protocol. The plan considers the severity of deformation and the structural role of the affected components. In light to moderate cases, where the frame shows mild bends or slight twists, technicians may pursue hydraulic pulling with careful, real-time laser feedback. The frame is anchored at strategic points, and a controlled force is applied to revert it toward its original geometry. The laser system monitors progress, preventing over-correction that could introduce new stresses or heat-affected zones. This approach preserves the metal’s innate strength while setting a foundation for subsequent alignment checks. In more stubborn situations, where simple straightening fails to bring the frame back within tolerance, heat-assisted correction comes into play. Thermal shaping lowers the yield strength locally by elevating temperatures to a precise range, typically around 600–800 degrees Celsius, making the metal more amenable to reshaping. Temperature control is critical; excessive heat can embrittle the structure, while inadequate heat can leave residues of distortion. A skilled technician executes the process with calibrated timing and a disciplined cooling sequence to avoid introducing stress patterns that could precipitate cracking later. These methods emphasize one core principle: repair decisions must be driven by measurable, repeatable data rather than force of will or intuition alone.

When damage is more severe—cracked rails, fractured crossmembers, or other structural failures that compromise the frame’s core integrity—the repair strategy shifts decisively toward component replacement. Removal of the damaged section requires precise cutting, and the replacement piece must be OEM-specification identical in material grade, thickness, and design. Welding, when necessary, uses inert gas shielding to ensure a clean, porosity-free joint that will behave like the original metal under load. Post-weld inspection becomes mandatory, employing non-destructive testing such as ultrasonic testing or radiographic examination to detect hidden flaws that could undermine strength. In cases where the damage is so extensive that repair would not restore the frame to safe, reliable condition, the entire frame or frame rail replacement is indicated. For heavy-duty applications, such as long-haul or high-capacity work trucks, the threshold for replacement is even more conservative, given the higher demands placed on the frame and the potentially catastrophic consequences of a compromised backbone.

Throughout this diagnostic journey, the overarching purpose remains constant: to restore the truck’s geometry, strength, and resilience so the vehicle can perform its duties safely and predictably. The post-diagnosis phase is more than a checklist; it is a disciplined sequence that ensures measurements, material condition, and process control converge at a single goal—reestablishing the frame’s original integrity. After the repair work concludes, a rigorous verification process validates that everything aligns with factory specifications. Dimensional checks confirm wheelbase, track width, and diagonal measures meet tolerance bands. A structural integrity test, whether through controlled loading or dynamic balance checks, validates that the frame behaves correctly under real-world conditions. Reinstalling the suspension and performing a full four-wheel alignment ensure that steering, braking, and handling are coherent with the vehicle’s intended geometry. In some jurisdictions, a formal safety certification accompanies the completion of repairs, signaling that the vehicle has undergone approved procedures and meets the necessary safety standards. This verification phase is not optional; it is the bridge between damaged reality and roadworthy reliability.

The diagnostic narrative does not exist in a vacuum; it threads into the broader fabric of vehicle maintenance philosophy. A well-conducted assessment informs more than the immediate repair. It shapes the expectations for durability, guides decisions about potential future reinforcements, and frames the vehicle’s long-term maintenance plan. The consequences of a hasty or superficial diagnosis extend beyond the repair bill. They affect tire wear patterns, steering response, and the vehicle’s crash-worthiness. That is why professionals insist on calibrated equipment, standardized procedures, and a mindset that treats the frame as a living system whose health must be tracked alongside every other subsystem of the truck. To those who contemplate DIY fixes, the message is clear: the complexity, the risk, and the stakes demand specialized expertise, precise instrumentation, and a formal process grounded in engineering best practices.

For readers seeking a deeper dive into the standards that govern these procedures, consider exploring industry references that discuss the underlying methodologies and verification requirements. In the broader context of frame repair, ongoing dialogue between diagnostic data and repair actions helps ensure the outcome is not merely cosmetic alignment but structural restoration. If you want to explore related perspectives on maintenance philosophy and how it connects to frame integrity, you can visit the broader reservoir of knowledge at the Master Truck Repair blog: mastertruckrepairllc.com/blog/.

The assessment and diagnosis phase thus stands as a critical discipline within the repair lifecycle. It is the stage where uncertainty is converted into a plan, and plan into action that honors safety, compliance, and the vehicle’s future reliability. When done with precision, care, and a clear eye on original specifications, it sets the stage for a repair that does not merely patch a problem but reestablishes the frame’s trust with every mile traveled. For practitioners, this is where expertise and responsibility converge, ensuring that the road ahead remains predictable and safe for drivers and their cargo. More detailed technical specifications, procedures, and case studies can be found in the SAE reference that informs the standards in this chapter: https://www.sae.org/technical-papers/2021-01-0745.

null

null

Beyond the Bend: Reclaiming Structural Integrity in Complex Truck Frame Deformations

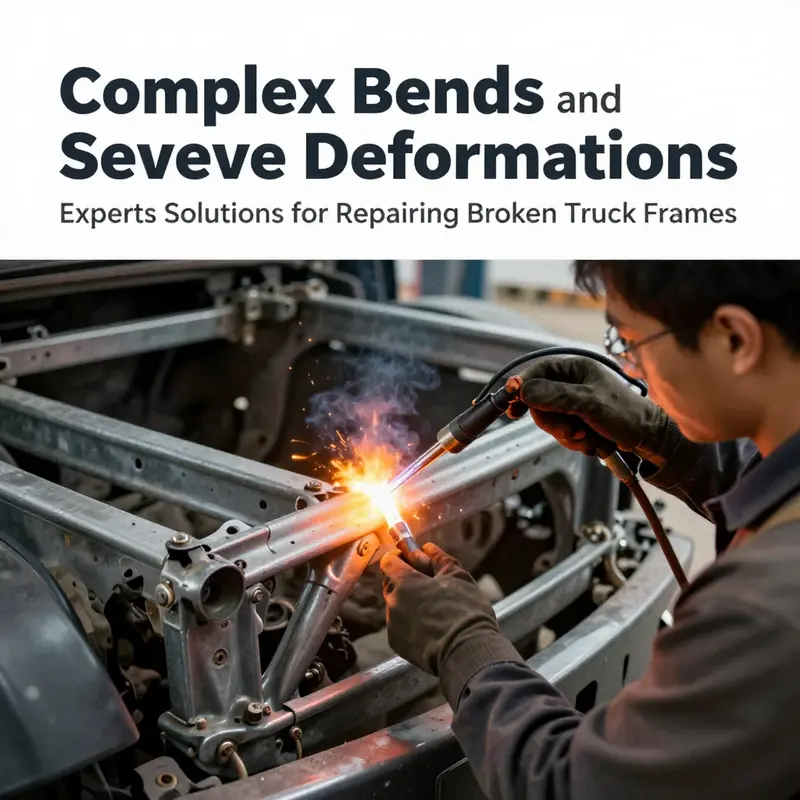

When a truck frame sustains complex bends or severe deformations, the repair task moves from straightforward fix to a meticulous reconstruction of the vehicle’s entire loading path. The frame is not merely a shell; it is the backbone that transfers every load, every collision impulse, and every dynamic force from suspension to drivetrain to the operator. Restoring it requires a disciplined sequence that begins with exacting assessment and ends only after the structure has proven its integrity through measurement, testing, and re-qualification. The aim is not cosmetic alignment or a temporary correction, but a restored, predictable geometry that preserves steering feel, tire wear characteristics, crashworthiness, and long-term fatigue life. In practice, this means engaging a precise workflow that treats the frame as a load-bearing carrier whose defects can cascade into handling anomalies or unsafe behavior if left unchecked. The chapters that precede this one lay out the general approach to frame repair, and this section focuses on the delicate middle ground where deformations have pushed the structure beyond minor misalignment but may still be recoverable without full frame replacement. What follows blends industry standards with engineering judgment, anchored by objective measurements rather than guesswork, and it emphasizes that the repair must be more than a patch—it must re-create the original stiffness, alignment, and strength of the frame.

Assessment and diagnosis begin before any tools touch metal. A visual inspection reveals the obvious: cracks, twists, dents, and any distortion that deviates from factory geometry. But a true diagnosis goes deeper. Modern repair practice relies on professional measurement using a 3D laser system or a frame alignment rack to map every critical dimension. Wheelbase and track width are not abstract numbers; they constrain steering geometry, suspension geometry, and the vehicle’s dynamic response. Diagonal measurements reveal twists that might be invisible to the eye but are fatal to predictable handling. The assessment must categorize the damage as a crack, fracture, twist, or general distortion, because the chosen repair path hinges on that classification. In this realm, experience matters as much as instruments. The technician not only reads the numbers but interprets what those numbers mean for load paths through the rails, crossmembers, and integral supports. This diagnostic clarity guides every subsequent decision and prevents over-correction, which can introduce residual stresses or altered geometry that compromise safety.

Once the extent and type of damage are quantified, the next step addresses structural integrity. The frame operates under high stress, and severe deformation may harbor stress concentrations or microcracks that are not immediately visible. Non-destructive testing becomes essential: ultrasonic scanning, magnetic particle inspection, or radiographic methods can expose subsurface flaws that would otherwise escape detection. The aim is to determine whether the metal within the deformed region retain enough ductility and strength after deformation to tolerate repair without re-cracking under service loads. Only after this assessment can technicians decide whether the damage lies within a repairable envelope or pushes the vehicle toward more radical measures. This stage reinforces a core principle: safety and reliability are non-negotiable, and skipping NDT invites hidden hazards that may emerge under load, fatigue, or collision forces years down the line.

With a clear map of damage and an understanding of material condition, the repair path unfolds in a logically connected sequence. For light to moderate deformation—minor bends or slight twists—the method centers on hydraulic pulling and controlled restoration of the frame to its original geometry. A calibrated hydraulic puller anchors to specific points on the frame, and force is applied gradually while real-time feedback from laser measurements guards against over-correction. The process minimizes heat input, thereby preserving the metal’s original strength and avoiding heat-affected zones that could alter fatigue characteristics. The technician watches measured diagonals, wheelbase, and track width as if reading a compass, ensuring no new misalignment is introduced even as the frame is coaxed back toward its nominal shape. This correction is refined work; it requires a balance of force and restraint, and it works best when the damage is not accompanied by cracks or fabricating defects in critical load paths.

When deformations become more stubborn or the bends more complex, heat-assisted correction enters the picture. Thermal shaping deliberately localizes heating to soften the steel enough to reshapes it without fracturing. Temperature control is paramount—temperatures typically in the 600–800°C range are used to lower yield strength briefly, enabling a more malleable adjustment. Yet heat is a double-edged sword. Excessive heat can embrittle the material, alter microstructure, or introduce new residual stresses that grow into fatigue cracks under cyclic loads. This is precisely why heat-assisted correction must be performed only by technicians with substantial experience in controlled heating and cooling protocols. After shaping, controlled cooling strategies are applied to minimize thermal gradients and residual stress, with post-action measurements confirming alignment and straightness. In many cases, thermal shaping serves as a bridge between gentle pulling and full replacement, enabling the correction of distortions that simple pulling cannot reconcile.

If the frame bears major damage—fracture in rails, crossmembers, or other critical load paths—the repair strategy shifts toward section replacement and welding. The damaged segment is removed with precision tools, and an OEM-specification replacement part is fitted and joined with inert-gas shielding to ensure a robust weld free of porosity and defects. The welding process becomes a crucial crucible for strength; it must maintain consistent heat input, joint compatibility, and material compatibility to avoid introducing weak points at the welds. Following welding, non-destructive testing is not optional but mandatory, to detect hidden flaws within the joint or surrounding areas. Ultrasonic testing or radiographic inspection can reveal voids, incomplete fusion, or microcracks that would compromise fatigue life. Strengthening this repaired region with additional gussets or reinforcement ribs is common practice, especially around high-stress zones such as rail-to-crossmember junctions. The objective is not merely to close a gap but to re-establish a continuous, fatigue-resistant load path that mirrors the original design’s resilience.

In the most extreme cases, when the frame has sustained catastrophic damage or repeated abuse that offsets the fundamental geometry beyond practical repair, full frame replacement becomes the only viable option. Modern heavy-truck frames are engineered around precise tolerances and standardized connections; removing a compromised frame and installing a new one requires alignment of mounting points, reestablishment of suspension geometry, and full requalification of the chassis as an assembly. Replacement is not an admission of defeat but a recognition that safety and reliability demand a fresh, uncompromised starting point. Even then, the work does not end with bolting in a new frame. The process includes rigorous alignment checks, reinstallation of the drivetrain and suspension, and a complete requalification cycle to restore factory specifications and regulatory compliance. This path is a last resort, reserved for cases where the structural integrity cannot be reconstituted through repair without compromising performance or safety.

All stages—from assessment to repair—are framed by a commitment to verification. After any repair, dimensional checks confirm that wheelbase, track width, and diagonals align with factory specifications. A structural integrity test, whether a load test or dynamic balance assessment, challenges the repaired frame under controlled conditions to ensure no unexpected deflection or imbalance surfaces during operation. The suspension system is reinstalled, and a full four-wheel alignment is performed to ensure steering and tire wear are predictable and safe. In some regions, safety certification or an official inspection is required before the vehicle can return to service, underscoring the idea that frame repair is not merely a mechanical task but a safety-critical process that must meet regulatory expectations. The overarching goal of this verification sequence is to re-create the vehicle’s original performance envelope, not just to fix a visible defect.

Throughout this journey, the profession’s emphasis remains unambiguous: frame repairs are high-stakes engineering tasks that demand specialized equipment, precise technique, and a disciplined adherence to process. DIY fixes are not only unsafe but likely to produce hidden weaknesses that surface under the stress of real-world operation. The frame is the structure that keeps everything else in line—the steering axis, the wheel-tire contact patch, the body mounting points, and the crash-absorption pathways. A repaired frame must restore not only straightness but the predictable behavior of the steering system, suspension geometry, and load transfer during cornering, braking, and propulsion. With complex bends and severe deformations, the margin for error narrows; the veteran technician reads the signs in measurements, negotiates the heat with restraint, and confirms every repaired joint with nondestructive testing. The result is not merely a corrected frame but a trustworthy chassis that enables the truck to perform safely across its service life. For readers seeking deeper context on safety standards and best practices, the official guidelines provided by authoritative bodies offer foundational references that underscore the seriousness of this work. See mastertruckrepairllc.com/blog for related planning and maintenance insights.

For those following the literature, the most authoritative reference on repair and requalification of damaged heavy truck frames discusses evaluation, repair processes, and re-certification standards for severely damaged frames. This material highlights that even when deformation seems localized, the frame’s load paths and internal microstructure demand careful scrutiny and a methodical repair approach. External professionals emphasize that the repair strategy must be tailored to the specific damage pattern, material grade, and intended service life, with a bias toward conservative, testable restoration rather than speculative repair. The SAE paper Repair and Requalification of Damaged Heavy Truck Frames remains a cornerstone reference, detailing criteria for determining repairability, recommended repair techniques, and criteria for requalification after repair. External reference: https://www.sae.org/publications/technical-papers/content/2019-01-0587/ .

In sum, complex bends and severe deformations do not spell the end of a truck’s service life when the frame remains structurally sound and repairable. The path requires a clear diagnostic thesis, disciplined control of heat and force, precise welding and reinforcement where needed, and rigorous post-repair verification. It is a craft that blends mechanical engineering with careful workmanship, where each measured value tells a story about how the frame carries its loads and how it must continue to do so. When executed by qualified professionals within a compliant framework, a damaged frame can be restored to its original integrity, preserving safety, performance, and the truck’s ability to carry the work forward rather than being relegated to the scrap pile.

When the Frame Fails: Navigating Major Damage and Fractures in Truck Frame Repair

The frame of a heavy truck is more than a backbone; it is the engineered pathway through which every load, maneuver, and collision energy travels. When major damage or a fracture occurs, the vehicle’s entire performance, safety, and service life hinge on a precise assessment and a disciplined repair strategy. This is not a patchwork fix. It is a structural intervention that must restore the original geometry, stiffness, and load pathways so the truck can carry weight, steer predictably, and survive in the harsh realities of road usage. In the most extreme cases, the frame’s integrity cannot be salvaged by cosmetic or partial repairs; the failure mode demands a surgical approach that considers dimensions, material behavior, and the exact design specifications intended by the OEM. The seriousness of the situation calls for a balance of engineering judgment, meticulous testing, and adherence to industry standards that govern how frames are repaired, strengthened, or replaced. The aim is not just to get back on the road, but to restore the truck to the safety margins, fatigue limits, and crashworthiness it had when new.

What begins as a visible dent or a slight twist can hide deeper, non-obvious flaws that only careful analysis reveals. A thorough inspection sits at the heart of any major-frame repair plan. Technicians start with a comprehensive visual survey seeking cracks, distortions, or misalignments that betray the frame’s inner condition. But eyes alone are not enough. The extent of damage, especially in critical areas such as main rails, crossmembers, mounting points, and seat belt anchors, requires precise measurement. A 3D laser measurement system or a dedicated frame alignment rack can map out deviations in wheelbase, track width, diagonal checks, and twists that are not readily visible. These measurements establish a baseline and guide the repair strategy. When the issue involves fractures or deep-seated deformities, nondestructive testing becomes essential. Ultrasonic testing can reveal hidden flaws inside the metal, while magnetic particle inspection helps identify surface and near-surface discontinuities in ferromagnetic materials. Together, these tools provide a fuller picture of the frame’s health and where any corrective work must focus. The assessment informs whether the problem is a crack, a fracture, a twist, or a broader distortion, and the repair choice grows from that diagnosis rather than from a single symptom.

If the damage is confined to minor misalignment or light deformation, the path is different from major fractures. Even then, precision is non-negotiable. In light to moderate cases, hydraulic pulling or stretching correction can be used to coax the frame back toward its original geometry. The process relies on anchor points, controlled force, and real-time feedback from laser measurement systems to prevent over-correction, which can introduce new stresses. A key virtue of this approach is preserving the metal’s original strength by avoiding excessive heating. Yet, as the saying goes, what fixes a bend may not address a hidden crack, and what looks fixable on the surface may hide sub-surface damage.

When the damage crosses into more stubborn territory—significant fractures or complex bends—the repair strategy shifts toward more robust methods and, when necessary, more substantial interventions. Heat-assisted correction can be employed to soften specific areas and facilitate reshaping. This thermal shaping must be executed with exacting temperature control, typically in the 600–800°C range, to lower yield strength just enough to permit reshaping without compromising the metal’s long-term toughness. The heat must be applied judiciously, followed by controlled cooling to avoid introducing new residual stresses or embrittlement. Only experienced technicians should perform thermal shaping because it carries the risk of material degradation if mismanaged. This approach is reserved for distortions that resist pulling alone and are not amenable to simpler corrective methods.

In the most severe scenarios—major damage or fractures that threaten the frame’s load-carrying capacity—the repair conversation moves to replacements and structural reconstitution. A damaged rail, severely compromised crossmember, or a mounting point that has yielded or cracked may require cutting out the affected section and welding in an OEM-specification replacement. Here, fidelity to original design matters more than ever. The replacement piece must match material grade, thickness, geometry, and the frame’s overall design intent. Welding demands a clean, controlled environment, typically employing inert-gas shielding to prevent porosity and ensure a durable joint. The joint’s integrity is not assumed; it is verified through non-destructive testing after welding. Ultrasonic inspection can confirm there are no hidden flaws within the weld or adjacent zones, and radiographic (X-ray) checks can reveal internal discontinuities that might escape the naked eye. Post-weld verification is not a formality but a necessity, aligning with the safety expectations of the most demanding applications.

When a single section cannot be saved, or when the damaged area lies within the critical load paths of the frame, replacing the entire frame section or even the full frame becomes the preferable option. This decision is not taken lightly. It reflects careful engineering judgment about the energy paths through the chassis, the compatibility with the truck’s suspension, drivetrain, and body mounting, and the ability to re-establish the original geometry with factory-like precision. Frame replacement is typically considered the safest course when structural integrity would be compromised by attempting to patch or reconstitute compromised rails. In all these scenarios, the repair must adhere to OEM specifications and prevailing industry standards, including guidance from recognized bodies such as ASME and SAE. The emphasis is on preserving predictable load distribution and ensuring that the vehicle’s dynamic response remains within tested and certified boundaries.

The risks of cutting corners at this stage are substantial. A repair that fails to restore the exact load paths or that leaves hidden defects can translate into catastrophic outcomes under heavy load, high torque, or sudden steering inputs. In a heavy-haul context, where trucks routinely carry substantial freight and operate under demanding conditions, the margin for error is small. Liability rises with the severity of compromise, and the consequences can extend beyond safety to regulatory noncompliance and costly downtime. This is why the industry steadfastly emphasizes rigorous inspection, strict adherence to OEM designs, and post-repair validation that includes dimensional checks, dynamic load considerations, and alignment verification. Only after these steps can a vehicle be considered fit for service again.

The narrative of major-frame repair also weaves in the broader context of professional responsibility. It is not a field where improvisation earns credibility. The complexity of frame geometry, the interdependence of components, and the critical nature of the frame to occupant safety demand a disciplined approach. Even welding—an age-old method—takes on a different significance here because the weld is a conduit for restoring continuity across sections that must act as a single, continuous structure. The practice requires not just technique but an understanding of how heat treatment, residual stress, and metallurgical properties influence long-term durability. The decision to repair versus replace hinges on a careful balance of cost, safety, available OEM specifications, and the expected life of the truck in service.

For technicians and shop managers, the practical path begins with a frank evaluation of the damage’s scope and ends with a documented repair plan that traces every measurement, every test result, and every corrective action. A robust plan includes confirmation of alignment and wheelbase consistency, ensuring that the repaired frame maintains the intended geometry to support proper suspension behavior and steering geometry. It also means orchestrating a seamless reassembly of components—mounts, brackets, driveline connections, and the suspension system—so the frame remains the correct foundation for the entire running gear. This is not merely about restoring a physical shape; it is about restoring a performance envelope that was engineered into the original design and validated through testing and regulatory oversight.

For readers seeking further practical guidance, a broad spectrum of maintenance and repair perspectives can be found in industry literature and professional blogs. These resources can provide context, examples, and procedural references that complement the technical emphasis of OEM guidelines and regulatory standards. See, for example, broad maintenance discussions within our own knowledge base for practical notes on keeping frames healthy during routine service intervals. You can explore more on our blog here: mastertruckrepairllc blog.

As the chain of reasoning above implies, the repair of a major frame damage or fracture sits at the intersection of engineering discipline and field-tested practice. It is a case where the cost, the time, and the risk of incorrect repair converge, and where the safest, most reliable path is to align with OEM specifications, apply rigorous non-destructive testing, and validate the result with comprehensive post-repair verification. The objective remains clear: restore the truck’s structural integrity so it can perform as intended, handle the rigors of heavy use, and protect the lives of its occupants and other road users. That is why professional frame repair is treated as a specialized service—an undertaking that reflects the seriousness of the frame’s purpose and the high bar set by industry standards. For practitioners and owners alike, recognizing the gravity of major damage and committing to a disciplined, standards-driven process is the only responsible course.

External resources for deeper technical procedures and safety frameworks are available from SAE International. Access to these guidelines offers detailed, procedure-focused insights that support the repair decisions described here. https://www.sae.org

Verifying a Repaired Truck Frame: Measurements, Tests, and Documentation for Safe Return to Service

Post-repair verification is the point where engineering skill, safety, and accountability converge. A repaired frame can look straight to the eye yet still harbor subtle distortions, residual stresses, or weak joints that compromise handling, tire life, and crash performance. This chapter walks through the verification processes that separate a cosmetic repair from a truly safe restoration. It explains the essential measurements and tests, the diagnostic checks that confirm electronic systems respond correctly, and the documentation that protects owners and shops alike.

Begin with precision measurement. After any structural work, the frame must be measured against factory specifications using a calibrated system. Modern shops use laser alignment rigs or 3D frame measuring machines that capture coordinates with millimeter accuracy. These tools compare current dimensions to the manufacturer’s original geometry: wheelbase, crossmember locations, track width, diagonal measurements, and ride-height reference points. Even a few millimeters of deviation in diagonal measurements can signal a twist that will affect steering and tire wear. Measurements should be recorded before and after repair so the technician and the vehicle owner can clearly see the correction achieved.

Measurements alone are not enough; they must be interpreted by a qualified technician who understands tolerances and load paths. The frame is an engineered structure. Some dimensions are critical to geometry and safety, others are service clearances. A competent technician determines which deviations are acceptable and which require further correction or replacement. This judgment relies on training and on access to up-to-date factory data. Shops should maintain a library of manufacturer specifications or subscriptions to technical databases so decisions are based on the correct reference points.

Visual inspection remains an important complement to laser-based checks. A thorough walkaround looks for weld quality, matching paint and seam appearance, distortion of mounting holes, and signs of residual stress such as small hairline cracks radiating from a repair zone. Welding must be visually acceptable and then verified by non-destructive testing when the repair involved load-bearing components. Ultrasonic testing, dye penetrant inspection, or radiography reveal flaws beneath the surface so a joint that looks fine does not carry hidden defects.

Load and functional tests replicate real-world forces. Static load testing places weight on the chassis at specific anchor points to confirm the frame supports expected loads without unexpected deflection. Dynamic checks include a road test focused on ride quality, steering response, and noise that can indicate internal looseness or misalignment. During these drives, pay attention to pulling, wandering, abnormal vibration, or uneven tire wear patterns. A proper four-wheel alignment must follow frame correction and be verified after suspension reassembly. This ensures steering geometry—caster, camber, toe—meets factory specifications and that tires will wear evenly.

Electronic systems increasingly factor into frame verification. Modern trucks rely on sensors mounted to the chassis and suspension for anti-lock braking, stability control, and driver assistance functions. Frame repairs can alter sensor positions or electrical grounding. Diagnostic tools should be used to scan for error codes and to reset or recalibrate systems as required. Specialized manufacturer-level tools may be needed to clear codes or recalibrate steering angle sensors and wheel-speed sensors. Confirming that warning lights remain extinguished and that electronic systems operate normally is part of a comprehensive verification.

Post-weld metallurgy matters when heat-assisted correction or welding was used. Excessive heat can embrittle steel or alter its fatigue life. When repairs required thermal shaping or welding on a critical rail, document the temperatures used, the welding process, filler metal specification, and any post-weld heat treatment. Where available, perform hardness testing or metallurgical spot checks to ensure the metal properties remain within acceptable ranges. If NDT finds irregularities, rework or section replacement may be necessary rather than accepting a questionable repair.

Precise, auditable documentation completes the verification process and protects all parties. A detailed post-repair inspection report should include original damage measurements, the repair process used, pre- and post-repair dimensional prints, NDT results, and alignment readings. Include photos that show the damaged area, the repair steps, and the finished work. If any manufacturer recalibration or software reset was performed, list the diagnostic tool used and the codes cleared. This report serves as proof of the vehicle’s condition and is essential for warranties, resale, or regulatory inspections.

Certification and compliance requirements vary by jurisdiction. Some regions require a formal safety inspection or structural certification before a repaired vehicle returns to the road. Repair shops should be aware of local rules and coordinate inspections as needed. A certified sign-off from a qualified inspector is often required for insurance or registration purposes and reassures buyers that the vehicle meets legal safety standards.

For buyers and fleet managers, insist on full repair records, alignment reports, and a clean post-repair inspection as conditions for purchase. A transparent verification package reduces risk and provides a predictable maintenance outlook. For repair professionals, meticulous verification supports business reputation and reduces liability. It can also protect warranty obligations and help identify repairs that need additional work before a vehicle leaves the shop.

A final point concerns preventive follow-up. Even a well-executed repair should be rechecked after a period in service. A short-term follow-up at a few hundred miles can reveal loosening clamps, settling of welded assemblies, or early signs of uneven tire wear. Encourage owners to return for a post-service inspection and to keep detailed maintenance records. That follow-up maintains confidence in the repair and can catch issues before they escalate.

Post-repair verification is not optional. It is the engineering audit that confirms the frame is safe, the alignment is correct, and vehicle systems function as intended. When measurement tools, testing methods, NDT, diagnostic scans, and clear documentation are combined, the repaired truck can return to service with confidence. For shops, it is the practice that substantiates professionalism; for owners, it is the protection that ensures safety and long-term value.

For additional perspective on evaluating repaired frames when buying a used truck, see this buyer’s guide external resource: https://www.caranddriver.com/truck-repair/article/a41234567/how-to-evaluate-pickup-truck-frame-damage-a-buyers-guide. For ongoing guidance on maintenance and record-keeping that complements post-repair verification, consult the Master Truck Repair blog.

Final thoughts

Repairing a broken truck frame requires a detailed understanding of various conditions and repair techniques. Fleet managers and trucking operators must prioritize comprehensive assessment methods, adopt appropriate repair strategies for varying levels of damage, and ensure rigorous post-repair verification. Understanding these elements not only enhances vehicle safety and performance but also significantly reduces long-term maintenance costs and operational downtime. By taking a professional approach to truck frame repair, businesses can ensure the sustainability and reliability of their fleets, ultimately contributing to safer roads and more efficient logistics operations.