Understanding the cost of truck rust repair is crucial for fleet managers, trucking company owners, and operators in construction and logistics. Rust damage, if left unaddressed, can escalate, affecting safety, compliance, and operational efficiency. This article will dissect the intricacies of rust repair costs from surface to structural damage, the significance of professional evaluations, and considerations for long-term investments. Each chapter aims to equip industry professionals with the knowledge needed to make informed decisions that enhance vehicle reliability and longevity.

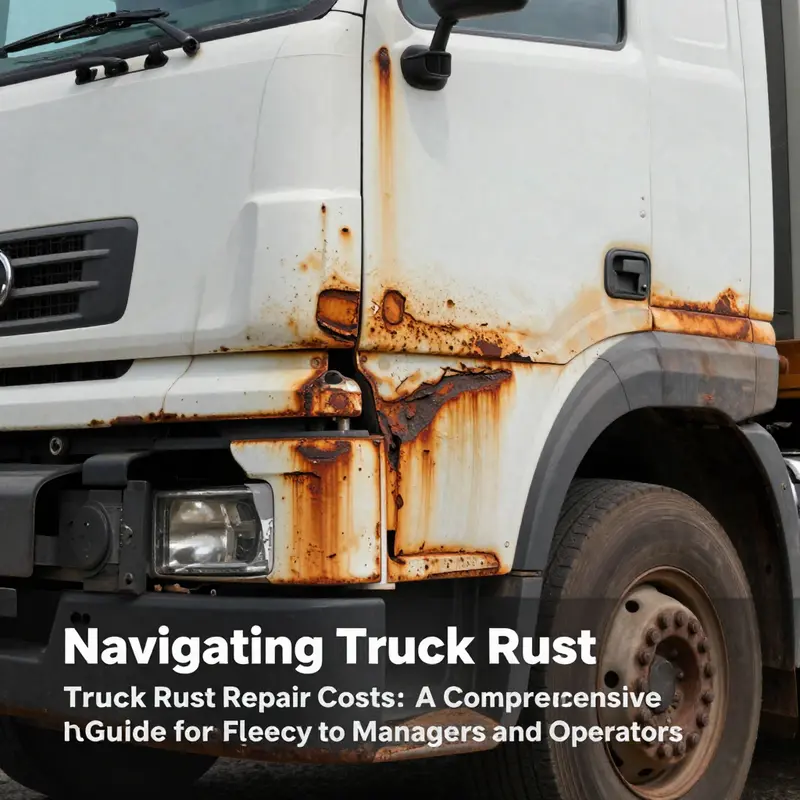

Rusted Realities: Navigating the Real Costs of Truck Rust Repair, from Surface Scrapes to Structural Breaks

Rust on a truck is more than a cosmetic blemish or a blight on a glossy finish. It can silently jeopardize safety, undermine reliability, and erode resale value long before a vehicle should be retired. When owners ask, how much for truck rust repair, they are really weighing the practical implications of corrosion against the realities of what it takes to restore integrity. In 2026, the cost landscape is wide, shaped by the extent and exact location of the rust, the type of truck, and the labor market in a given region. A small surface patch can be repaired for a modest sum, while rust that has eaten into frame rails or suspension mounts calls for a different scale of effort and expense. The numbers aren’t just about metal and paint; they reflect the precision required to return a vehicle to safe, dependable service and the tradeoffs between extending a life on the open road and replacing a machine whose wear patterns have altered its safety profile. The chapter that follows threads these realities together, offering a cohesive view of how costs accumulate, what drives them, and how a careful budgeting mindset can reduce surprises without compromising safety or performance.

Surface rust is where many owners begin their conversations with repair shops. It is, in its essence, an outer-layer problem. The rust may be confined to the paint and the very first millimeters of metal, often appearing as flaking, speckling, or small pits around wheel wells, door sills, and the undercarriage. In these cases, the repairs are straightforward, and the financial impact tends to stay within the low to mid hundreds of dollars, sometimes less. The typical process involves sanding away the rusted spots, priming the bare metal to halt further corrosion, and repainting to restore the finish. Minor touch-ups and sanding can keep costs in the range of roughly fifty to two hundred dollars, depending on the area that needs attention and the ease of access. Even when the rust looks minor, a thorough job is essential to prevent a repeat cycle—scuffed primers can fail, moisture can seep behind a fresh coat, and small crevices can trap grit that accelerates deterioration. The technician’s goal in these situations is not merely to restore appearance but to seal off the moisture pathways that fueled the rust in the first place. A competent shop will also check for any underlying issues that might not be visible from the outside, such as hidden corrosion under trim pieces or along edges where water collects during routine driving or washing. For many operators, surface rust is a cost of doing business rather than a crisis, a maintenance dent that is predictable and affordable if treated promptly. That predictability is valuable, because it means a truck owner can budget for these repairs as part of routine maintenance rather than facing an unexpected bill when the rust spreads.

What makes surface rust tolerable in cost terms is that, at this stage, the structural integrity of the truck remains intact. The metal has not been compromised where it matters most for load-bearing capacity or steering geometry. Yet the boundary between surface and structural rust can blur in an instant, and the moment rust begins affecting welds, joints, frame points, or cross-members, the calculus changes dramatically. Structural rust is more than a blemish; it is a safety and performance risk. When corrosion penetrates deeper into critical components—frame rails that support the entire chassis, anchor points for suspensions, or mounts that secure essential assemblies—the repair becomes an engineering challenge as much as a metalwork task. In these cases, the rust has the potential to alter a vehicle’s stiffness, alignment, and ability to carry or withstand dynamic loads. The cost implications reflect this increased complexity. Rather than a modest series of prep steps and a repaint, a structural repair often involves substantial disassembly, precise measurement, and work that must meet strict safety standards. Welding may be required to rejoin or replace compromised sections, followed by the installation of new metal panels and an anti-corrosion treatment plan that can extend the life of the repair and protect surrounding areas from renewed attacks by road salts, moisture, and road grime. The numbers shift quickly here, and this is where many shop estimates begin to differ widely depending on the truck’s model, the severity of the rust, and the labor rates in a given region. Costs commonly cited in industry discussions begin in the upper end of the thousands for significant structural work and can exceed four thousand dollars, especially when the frame or a large portion of a structural member needs to be replaced or reconstructed. It is not unusual for larger commercial trucks to present even more ambitious price tags, given the material costs of heavy plates and the precision welding and alignment work required to preserve safe handling and weight distribution. The reality for managers who rely on fleets is that a structural repair often triggers a reassessment of the vehicle’s ongoing viability in service. If the rust has created soft spots, thin sections, or distortions in the frame, the repair must restore not only a clean surface but also a verified stiffness and a guaranteed baseline for safety and compliance. In some scenarios, the cost of restoring a frame to like-new condition can approach or even exceed the truck’s current market value, provoking a strategic decision about repair versus replacement. This is not merely a financial calculation; it is a risk assessment, a question of uptime, cargo safety, and the long-term consequences of operating a compromised frame under heavy loads or in challenging road conditions.

The factors that push the cost from a surface fix into the realm of structural repair are well understood in professional settings, but they still surprise some owners who expect a consistent price ladder. The truck’s model and its age matter in predictable ways. A newer, lighter-duty chassis typically has less extensive corrosion-prone areas and may be repaired with simpler, less costly techniques. A heavy-duty chassis, designed to carry substantial payloads, features larger frame sections and a more complex web of cross-members and attachment points. When rust invades axles, hubs, or suspension mounting points—areas critical to weight transfer, steering control, and wheel alignment—the repair becomes a multi-disciplinary effort. It demands precise welding, potentially panel replacement, and selective reinforcement to ensure the vehicle continues to meet the safety margins required for highway operation. In many cases, the assessment will also consider the axle and suspension components for corrosion-related wear that could affect alignment, balance, or ride stability. The labor cost for such work rises not only because of the technical skill required but also because the job often necessitates specialized tools and jigs that ensure welds are clean, aligned, and ready for corrosion protection. The price escalates further if the rust has created holes or if the metal has thinned to the point where structural integrity is in question. In these situations, the professional evaluation may reveal the need for partial or complete frame reconstruction, which marks a turning point in both the repair plan and the financial equation. It is precisely because structural rust carries far-reaching consequences that buyers and operators should approach quotes with a clear understanding of what is driving them and what the long-term implications might be for safety, warranty coverage, and resale value.

From the vantage point of a fleet or a single owner-operator, the decision on how to address rust hinges on several practical realities. First is the extent of the damage, which is not always easy to quantify from a quick glance. A trained technician will perform a thorough inspection, probing hidden corners of the undercarriage, inspecting welds, and measuring any misalignment or flex in the frame. This diagnostic phase, while an additional cost, is indispensable for producing an accurate quote. Second is the componentry that bears the weight of the load. If rust has compromised frame rails or cross-members that bear the brunt of dynamic forces, replacement parts may be necessary rather than patchwork fixes. Third is the availability of skilled labor and materials. In many markets, certified welders and auto body technicians who specialize in structural repairs command premium rates, especially if the work must be done to meet safety standards and regulatory expectations. Finally, there is the variable of regional price differences. Labor rates in metropolitan areas and regions with high demand typically push quotes upward, influencing not just the initial repair bill but also the total time a vehicle spends out of service. A truck might be kept off the road longer than the initial estimate would suggest if the rust problem is multifaceted and requires coordination between body shops, machine shops, and testing facilities before the vehicle is deemed roadworthy again. The interplay of these factors creates a spectrum of possible outcomes, and the most prudent approach is to obtain multiple quotes that reflect a consistent diagnostic scope and an agreed-upon repair plan. Yet even with careful comparisons, owners should be mindful that the cost guidance from one shop to the next can vary substantially when the underlying assumptions differ—whether one estimate assumes full frame reconstruction, while another contemplates selective reinforcement with patch panels and extended anti-corrosion treatments. This is one reason preventive practices and early detection are so valuable; they keep the scope manageable and the repairs affordable while preserving safety margins that protect people and cargo alike.

Preventive measures, when implemented consistently, are arguably the most cost-efficient approach to rust management over the life of a truck. Undercoating, wax coatings, and timely cleaning after exposure to road salts in winter climates create barriers that slow corrosion’s progression and give owners a longer window before a structural repair becomes necessary. The costs of these measures are generally far lower than the sums needed for deep structural remediation. Undercoating, for example, adds a modest annual expense but pays dividends by reducing the rate at which rust penetrates critical steelwork. Regular washing, especially around wheel wells, sills, and the undercarriage, is another straightforward habit that mitigates the accumulation of salt and moisture that accelerate rust. For those operating in regions where winter road treatment is common, investing in a proactive rust-prevention regime can be a decision with tangible payoffs in uptime, resale value, and the likelihood of passing inspections. The broader lesson here is that rust is a condition with a lifecycle: it starts as a surface issue, may stay superficial for a while, and can then advance into structural concerns if left unaddressed. Those who monitor the metal’s condition with routine checks and a planned maintenance schedule can calibrate the timing of inspections to correspond with the vehicle’s service life, typical duty cycles, and exposure to corrosive environments.

To translate these insights into practical planning, owners should think in terms of ranges rather than single-point estimates. A routine surface repair could be absorbed into a maintenance budget without sending shockwaves through cash flow, while a major structural repair can demand a larger allocation and a clearer justification, especially if the vehicle operates in a high-utilization context or carries high-value loads. The cost uncertainty is not a flaw; it reflects the real-world variability in rust’s pattern and the theater of work required to restore a vehicle to its original, safe operating condition. In practice, this means establishing a few guardrails: a preferred range to guide decision-making after diagnostics, a plan for follow-up inspections, and a readiness to explore alternatives if the rust’s escalation threatens uptime or safety. For instance, a responsible maintenance strategy might involve setting aside a budget for minor surface repairs on an annual basis, while reserving a separate contingency for potential structural repairs that could arise over a multi-year horizon. When added together with routine maintenance costs, this approach provides a clearer financial map and reduces the likelihood of an unpleasant surprise should rust begin to threaten structural integrity.

An important consideration, often overlooked, is how a rust repair fits into the broader context of fleet management and vehicle lifecycle planning. For owners who manage multiple trucks, the decision framework becomes even more nuanced. A rust repair on a single unit could be justified by its role in the fleet and its expected remaining service life. Conversely, if a truck is already nearing the end of its useful life, a structural repair might be deemed economically irrational, prompting discussions about replacement rather than repair. In either case, the financial math should incorporate not only the immediate repair cost but also ongoing maintenance costs, expected downtime, and the vehicle’s residual value after the work is completed. This is where a disciplined budgeting approach—taking into account maintenance cycles, repair forecasts, and potential salvage or resale scenarios—becomes essential. The practice of budgeting for routine maintenance, including rust-related care, reduces the likelihood that a significant rust event will derail operations, and it supports more predictable cash flow planning for a fleet. It also creates space for a more strategic conversation about capital expenditure, the pace of fleet renewal, and the allocation of resources toward safety upgrades that may come with newer chassis designs or improved corrosion protection technologies. A practical way to begin is to document rust-related costs alongside other maintenance expenses, track the frequency and severity of rust incidents by vehicle type and climate, and use that data to refine both preventative programs and replacement timelines.

For those who want a concrete roadmap, there are reliable guidelines and industry insights that can frame the budgeting conversation. A prudent approach starts with a disciplined diagnostic that distinguishes surface from structural rust and then follows a staged repair plan aligned with safety and compliance imperatives. When rust is just beginning to surface, a quick intervention is usually all that is needed to restore appearance and halt progression. If rust has penetrated structural regions, the plan must prioritize restoration of load-bearing capacity, proper alignment, and long-term protection against re-encroachment by moisture and salt. The repair plan should also include a robust anti-corrosion treatment protocol, because the protective layer can decide how long the repaired sections last before another issue emerges. The cost implications of these choices become clearer when the repair steps are laid out in a transparent sequence: inspection and assessment, material replacement or reinforcement, welding and fabrication, anti-corrosion treatment, finishing and repainting, and finally post-repair inspection and requalification for safety standards. In many cases, a detailed, itemized quote from a reputable shop will spell out each of these steps and their estimated costs, which helps owners compare options and avoid hidden charges. In addition, the decision to pursue repair versus replacement is often anchored in a broader assessment of economic value and risk—what the vehicle can still safely do, how critical its uptime is to operations, and how the repair aligns with long-term fleet goals. For operators who want to align rust repair decisions with broader maintenance planning, a guiding question should be: does addressing rust now preserve the half-life of this truck’s usefulness, or does it merely postpone an investment that would be wiser to allocate toward a newer asset?

Understanding the landscape also means recognizing that rust repair is not a one-size-fits-all endeavor. The costs discussed here reflect typical ranges observed in professional practice, but they are not universal prices. Shop capabilities, the availability of skilled welders, the presence of specialized jigs and measurement tools, and the local cost of materials all influence the final bill. Some shops may offer bundled services that include rust assessment, welding, coating, and a warranty on the corrosion protection system, while others bill separately for each stage of the process. In a practical sense, therefore, a realistic budgeting target often incorporates a contingency that accounts for potential additional work that emerges during disassembly or due to hidden corrosion. This contingency is not a sign of bad planning; it is a prudent hedge against the unknown, a recognition that rust can reveal itself piece by piece as a project progresses. With that in mind, responsible owners approach rust repair with both care and strategy: they seek clear diagnostic findings, they request transparency in pricing, and they insist on workmanship that adheres to safety and durability standards. They also pursue preventative measures to reduce the likelihood of recurrence, planning for ongoing inspections and maintenance that extend the life of the repaired structure as well as the rest of the vehicle.

For readers seeking a practical anchor, the information above aligns with 2025 estimates and the continuing dialogue within the repair community about rust costs. It is helpful to remember that, in many cases, rust repair is as much about preserving safety and reliability as it is about restoring appearance. When approached with a full understanding of the risk profile and the repair pathway, owners can make informed choices that balance immediate needs with long-term performance. To keep the budgeting process grounded, consider leveraging resources that discuss routine maintenance budgeting in depth, such as dedicated guidance on how to plan for recurring maintenance costs and how to allocate funds for unexpected repairs. This approach does not only protect a vehicle’s value; it also protects a business by keeping uptime steady and reducing the probability that corrosion-related failures will disrupt operations during peak periods. For those who want a concrete starting point, a sensible first step is to arrange a diagnostic with a trusted technician who can translate rust into a clear repair plan with a corresponding cost estimate and a realistic timeline. Once that framework is in place, the path from surface rust to a durable repair becomes a matter of disciplined execution, careful choice of materials, and a commitment to ongoing anti-corrosion protection. This is the heart of turning a rust challenge into a managed risk, and it is how responsible operators keep their fleets on the road while staying within reasonable budgetary boundaries.

To support ongoing learning and planning, consider exploring the broader maintenance resources that address the budgeting and scheduling of routine truck care. Budgeting for Routine Truck Maintenance provides a framework for thinking about recurring costs, contingencies, and lifecycle planning that can help tame the financial unpredictability around rust and other wear-related issues. While rust costs themselves can be highly variable, a disciplined budgeting approach helps ensure that when a rust repair decision arrives on the calendar, the funds and the plan are ready. In the end, the goal is not simply to repair metal but to preserve a vehicle’s safety, reliability, and useful life while maintaining a clear view of the total cost of ownership—now and into the future. For authoritative industry guidance on the cost dynamics of truck rust repair and the standards that govern proper repair practices, readers may consult official resources from the automotive service community that address the specifics of rust-related diagnoses, repair methods, and safety compliance. ASE resources on truck rust repair costs

How a Professional Rust Inspection Shapes the True Cost of Truck Repairs

How a Professional Rust Inspection Shapes the True Cost of Truck Repairs

A professional evaluation does more than assign a dollar figure to a repair. It defines the difference between a manageable maintenance expense and a major structural overhaul that can ground a truck. For anyone asking “how much for truck rust repair,” the single most important step is a thorough, expert inspection. That assessment reveals not only what work must be done today, but what problems are likely to emerge later. It also frames the repair options, timelines, and realistic cost ranges.

A trained technician begins with a systematic approach. They inspect visible body panels and wheel wells, then move to the undercarriage, frame rails, suspension mounts, and axles. On heavy trucks, they check crossmembers, kingpins, spring hangers, and any fuel or air system lines near corroded areas. The inspector looks for flaking paint, bubbling, and any signs of metal loss. More crucially, they probe suspect areas to find hidden corrosion. Rust often hides beneath paint, under coatings, and along seams. Low-cost surface rust can require only sanding and repainting. But once rust penetrates, repairs may involve panel replacement, welding, or even frame reconstruction. Those procedures demand skilled labor and specialized equipment, driving costs up.

The scope an inspector uncovers directly affects the estimate you receive. For minor surface rust on a small area, the technician may recommend spot sanding, rust converter application, and touch-up paint. Costs for these jobs often start in the low hundreds of dollars—commonly between $50 and $200, depending on labor and materials. When rust is moderate to severe, the inspector will quantify metal loss and identify parts that need replacement. Panel replacement and welding on light to mid-duty trucks typically move estimates into the $300 to $1,500 range. For heavy-duty trucks or cases where rust compromises structural members, expect much higher figures. Repairing or replacing frame rails, axle mounts, or other critical load-bearing components can cost from $1,500 to $4,000 or more. The cost rises with truck size and complexity.

Local conditions shape these numbers significantly. In regions with high humidity, salty air, or frequent road salt use, corrosion progresses faster. Areas with import tariffs or limited access to replacement panels see higher parts prices. Cities with fewer certified heavy-truck shops may charge more for labor because of scarce expertise. For example, truck owners operating in certain urban environments often face both higher parts costs and longer wait times for qualified technicians. Those factors should be expected in estimates and discussed during the inspection.

Beyond raw costs, a professional evaluation identifies safety and compliance concerns. On commercial trucks, rust that affects suspension or frame components is not merely cosmetic. It can alter geometry, reduce load capacity, and create failure points that endanger drivers and cargo. Certified technicians can point to industry thresholds for acceptable wear. They also know when a compromised component must be replaced rather than patched. Repairs that restore structural integrity typically involve welding with proper penetration, reinforcement plates, and corrosion-resistant coatings. Each of those steps adds labor time and specialized consumables, and experienced shops will factor them into a transparent estimate.

A good inspection report also separates immediate needs from deferred maintenance. Truck owners frequently use that distinction to plan spending. The inspector will highlight critical repairs requiring immediate action. They also list non-critical rust issues that can be monitored or scheduled into a maintenance program. That prioritization helps owners manage cash flow and safety simultaneously. A precise evaluation gives you a defendable basis for negotiation when buying a used truck, and it provides a clear road map when budgeting for repairs.

How repairs are performed influences price as well. Welding in place may be cheaper than removing a panel and installing a factory-replacement part. However, welding alone can be insufficient if corrosion has eaten through surrounding structure. Certified shops often recommend cutting out the damaged metal and welding in new sections, using proper backing and plating where needed. That process is time-consuming and requires skilled welders who understand the stresses trucks endure. For heavy-duty vehicles, repairs may also use thicker gauge steel or reinforcement members to meet original strength specifications. Those choices increase material costs. They also lengthen shop time, which increases labor charges.

Parts sourcing is another cost driver. When local aftermarket panels are available, owners might save on parts cost. But for some heavy truck models, authentic or OEM-equivalent components come from overseas. Import duties, shipping, and lead times then become part of the cost. Shops operating in regions with high tariffs or limited logistics capabilities may pass those costs on to the customer. In these cases, a professional evaluation will include options: a repair that uses locally available parts today, or waiting for OEM components that ensure a longer-term fix. The inspector should explain tradeoffs in durability and total lifecycle cost.

An inspection also clarifies diagnostic steps that add to the estimate. Rust can cause electrical faults, brake line corrosion, or fuel-system leaks. The inspector may recommend pressure testing brake lines, checking air system integrity, or performing alignment checks after frame repairs. These diagnostics are separate line items on an estimate, but they are essential. They prevent repeated visits and uncover hidden failures. A repair that includes appropriate diagnostics and testing often costs more up front. Yet it reduces the chance of costly, unexpected breakdowns later.

Documentation from a professional evaluation adds financial value. Written reports that include photos, measured metal thickness, and a clear list of recommended repairs give you leverage. If you are buying a used truck, you can negotiate price or require the seller to address specific items. If you own the truck, the report helps prioritize spending and justify expenses to a fleet manager or lender. For fleets, consistent inspection records help track corrosion trends across vehicles. That information supports targeted preventive measures and more accurate budgeting for long-term repairs.

Choosing a qualified inspector matters. Look for technicians familiar with heavy-truck standards. Certifications and experience with common truck frames and suspension systems reduce the chance of missed issues. Shops with welding certifications and structural repair experience will better estimate the true scope of work. A professional familiar with local conditions can anticipate the hidden costs unique to your operating environment. They will consider climate, road conditions, and local parts supply. An effective inspector explains not only what to repair, but why each repair matters for safety and vehicle life.

Cost transparency should be a priority. A reliable evaluation breaks down estimates into labor, parts, and consumables. Labor is often quoted as shop hours at a set hourly rate. Parts should be listed with source and approximate lead time. Consumables include primers, weld rod, sealers, and anti-corrosion treatments. When a quote lumps everything into one figure, ask for details. A detailed estimate gives you options. For instance, you might choose an interim repair to keep a truck running while you source OEM parts. Or you may choose a full structural repair now to avoid repeated work.

Insurance and warranties intersect with inspection outcomes. Some repairs, particularly those involving safety-critical components, may be eligible for warranty coverage if performed by authorized facilities. Insurers sometimes require documented proof of necessary repairs before paying a claim. A professional inspection generates the kind of documentation insurers accept. For fleet operators, documented repairs can improve resale value if records show thorough, timely maintenance.

Inspection timing affects costs. Early detection saves money. Surface rust treated promptly requires less labor and fewer parts. Regular inspections, ideally every few months for trucks operating in harsh environments, catch early corrosion. For trucks in areas with salt exposure, more frequent undercarriage checks are prudent. Investing in routine inspections often pays for itself by avoiding large structural repairs later.

A professional evaluation can steer you to cost-saving alternatives. In some cases, the technician may suggest methods to stabilize rust and extend service life rather than full replacement. These methods include localized plating, rust neutralizers, and high-quality sealing compounds. They buy time and preserve structural components until a more permanent repair is practical. Shops may also recommend anti-corrosion treatments that slow future deterioration. While these treatments add to the immediate bill, they reduce the likelihood of larger repairs later.

When facing a large estimate, owners should seek multiple evaluations. Different shops bring different expertise and repair philosophies. One shop may specialize in cosmetic restoration, while another focuses on certified structural repair. Comparing written estimates helps you understand the range of acceptable methods and prices. Be cautious of extremely low bids that omit required diagnostics or testing. Low-cost quotes that appear too good to be true often cut corners, leading to recurring problems.

For buyers, an inspection report becomes a negotiation tool. It makes the true cost of ownership visible. You can ask the seller to reduce the price or to perform agreed repairs before transfer. A transparent, itemized inspection reduces surprises post-purchase, making budgeting and financing decisions more reliable.

Finally, use the inspection outcome to plan preventive measures. A shop’s recommendations often include routine maintenance steps you can apply immediately. These may include regular cleaning of undercarriage components, washing salt from hard-to-reach nooks, and applying protective coatings. For fleet managers, creating a maintenance schedule based on inspection findings helps distribute repair work across budget cycles.

If you need help planning a repair budget after an inspection, consider building a repair reserve. A structured emergency fund helps cover unexpected structural repairs without creating cashflow pressure. For guidance on building that type of reserve, review a practical guide on setting aside money for truck repairs here: building an emergency repair fund for truck owners.

A professional evaluation is not an optional step. It is the single action that clarifies whether your truck’s rust problem is inexpensive to fix or requires major structural work. The inspection frames the repair strategy, sets realistic cost expectations, and identifies compliance and safety risks. With a clear report, truck owners and buyers make informed decisions, prioritize investments, and avoid unnecessary expense.

For further reading on typical rust repair costs and approaches, consult an established reference on rust repair costs: https://www.carinterior.com/how-much-does-it-cost-to-fix-rust-on-a-car/.

Beyond the Patch: Building Long-Term Value Through Truck Rust Repair Investments

Rust is rarely a standalone problem in a heavy-duty vehicle. It is a symptom of exposure, time, and the harsh physics of metal and environment interacting under load. When viewed through a long-term lens, rust repair becomes not a single expenditure but a strategic maintenance decision that shapes a truck’s lifespan, safety profile, and resale trajectory. The real question for a thoughtful owner or fleet manager is not only how much a patch costs today, but how a well-planned repair will influence reliability, downtime, and total cost of ownership over years of operation. In this frame, the repair is less about salvaging appearances and more about preserving structural integrity in ways that protect workers, cargo, and the investment embedded in each axle, frame rail, or floor pan. The logic is simple but powerful: early, well-executed prevention and repair yield quiet savings later, even when upfront invoices appear steep. The aim is to forestall cascading failures that could force expensive replacements, unplanned downtime, or regulatory concerns that erode asset value and fleet credibility. This perspective reframes rust work from a cosmetic expense into a disciplined investment in the vehicle’s continuing utility and safety. Before any work begins, the mindset shift matters as much as the tools and materials that follow. When you start with the belief that rust repair is a long-term investment, you begin to prioritize quality, precision, and comprehensive coverage over quick fixes that look inexpensive but prove costly with time. The endgame is a truck that remains dependable, compliant, and predictable in its performance across seasons, routes, and loads. It is about building a maintenance culture, not chasing an aesthetic patch on a failing structure. In practical terms, this means recognizing that rust damage often starts small but can advance rapidly in critical areas if left unchecked. The cost curve of rust repair follows a familiar pattern: modest, discrete interventions early on can avert the need for larger, more invasive work later. A cautious, proactive approach to rust is a form of risk management—one that translates directly into reduced downtime, safer operation, and steadier total ownership costs. This chapter treats rust repair as part of a broader maintenance ecosystem, where inspection intervals, treatment choices, and repair techniques interact to influence lifetime value. When framed this way, the decision to repair becomes a proactive choice rather than a reactive reaction to an emerging flaw. The significance of this shift becomes especially clear for heavy trucks that carry people, equipment, and time-sensitive freight. In such contexts, even small rust-driven weaknesses in frame rails or suspension components can translate into larger safety concerns and regulatory exposure. Keeping a truck rust-free, therefore, is not merely about keeping paint intact; it is about preserving the structural resilience that makes a vehicle trustworthy in demanding operating environments. This relationship between rust control and reliability underpins every budget line and every planning session, from the first diagnostic to the final restoration of a compromised section. The overarching principle is straightforward: invest in robust repairs now to minimize the risk of major, disruptive failures later. That principle also guides the selection of materials and methods, which in turn shapes long-term outcomes. When durability and corrosion resistance are prioritized, repairs tend to last longer, downtime is reduced, and the vehicle remains compliant with safety standards. The longer a repair endures, the greater the return on investment, even if the upfront cost is higher than a quick fix. In practice, long-term value arises from several interlocking decisions. The first is accurate assessment. A comprehensive inspection that targets frame rails, floor pans, and suspension components helps quantify both current damage and potential future risk. This step is essential because it reveals the repair scope and the necessary sequence of work. The second decision is material selection. Choosing epoxy primers, rust converters, and high-grade steel patches is not cosmetic; it directly affects durability and resistance to future corrosion. Third, execution quality matters. Modern welding, precise shaping, and correct panel fit ensure that repairs restore original geometry and load paths. When done properly, a repaired area behaves as if it had never corroded, preserving the intended strength and stiffness of the surrounding structure. As a result, the truck remains safe to operate and capable of meeting the demands of its assignments over time. The financial story here is not a simple invoice total. It is a narrative about risk distribution and resource allocation. Early-stage investments in rust mitigation distribute the potential cost of future failures across a longer horizon, smoothing volatility in maintenance budgets. Fleet managers who think in terms of lifecycle costs often find that modest, well-timed repairs do more for total cost of ownership than larger, rare replacements in later years. The long horizon also motivates a disciplined approach to record-keeping. When rust repair work is documented with precise measurements, material specifications, and welding methods, the vehicle’s maintenance log becomes a valuable asset. It provides transparency for audits, resale assessments, and compliance reviews. It also enables better planning for preventive treatments and diagnostics in future cycles. In that sense, documentation is not bureaucratic overhead; it is a practical tool for forecasting and decision-making. The literature on rust repair emphasizes a few persistent truths that align with a long-term investment mindset. One truth is that surface rust and penetrating rust exist on a spectrum, and untreated surface corrosion can become a problem if moisture, salt, and road debris persist. Another truth is that certain zones are non-negotiable from a safety and structural standpoint. Frame rails, critical floor regions, and suspension anchor points carry loads and dynamic forces; deterioration here can compromise safety and ride quality. A third truth is that the cost of repair scales with the extent of damage and the rigor of the restoration. Small touch-ups are affordable and can be completed quickly. But when rust has breached into structural members, the project involves more hours of labor, more specialized equipment, and a greater commitment to corrosion protection. To translate these truths into practical action, owners and operators should view rust repair within the context of a maintenance roadmap that unfolds over years rather than as a single event. The roadmap begins with a careful assessment of the current state and a candid discussion about what is feasible and what is prudent over the vehicle’s expected service life. From there, the strategy moves through a sequence of decisions: whether to repair or replace, which materials to employ, and how to implement protective measures that minimize reoccurrence. Each decision has ripple effects on downtime, fleet utilization, and downstream costs. For instance, choosing epoxy primers and rust converters early in the process can significantly extend the life of repaired sections by creating a more durable barrier against moisture ingress. Selecting high-grade patches that match the original gauge and contour of the metal helps preserve the frame’s load paths and overall stiffness. When these choices are paired with precise welding techniques, the repaired area can integrate with the existing structure in a way that mirrors factory performance. This alignment matters not only for safety but also for resale value, as buyers increasingly seek trucks with rigorous, documented corrosion control histories. The cost implications of these decisions depend on the repair scope and the vehicle type. Surface rust removal and cosmetic touch-ups are the most economical entry points, often starting in the low hundreds of dollars for small vehicles and modest surfaces. The more substantive route—addressing structural rust in frame rails, floor pans, or critical suspension linkages—entails higher labor costs and more substantial material needs. In heavy-duty trucks, where frames and axles carry substantial loads and endure long service life, repairs frequently require more extensive labor, more complex diagnostics, and sometimes panel replacement. In many cases, the operations layer must include corrosion protection strategies such as undercoatings or wax-based sealants that persist through harsh seasons and repeated exposure to road grime. These preventive measures are not cosmetic; they act as ongoing defense systems that reduce the likelihood of rust returning to critical areas. The long-term value of proper rust treatment often equates to lower downtime and fewer unplanned repairs in the future. When a truck misses a scheduled run due to rust-related failures, the cost is not just the service interruption. It is the cascading effect on customer commitments, fleet reliability metrics, and driver morale. By investing in preventive measures—annual or semiannual inspections, after-winter evaluations, and proactive coating maintenance—fleet operators can stabilize uptime and create more predictable maintenance calendars. This predictability translates into more stable dispatching, higher on-time delivery rates, and better utilization of capital equipment. From a resale perspective, rust-free history and a well-documented repair sequence contribute to higher market value. Buyers, including fleets and owner-operators, often scrutinize the rust repair narrative: the regions addressed, the materials used, and the longevity of the fix. A well-executed repair that preserves the original geometry and continues to perform under load speaks to the vehicle’s reliability and the care exercised by its owners. Conversely, a patchy or poorly documented repair history can undermine buyer confidence and depress bids. The interplay between repair quality and resale value is more pronounced in commercial markets where fleet cycles and depreciation schedules determine financial outcomes. In this context, the choice of repair technique matters just as much as the choice of parts. Modern methods—when properly applied—support a return to factory-aligned tolerances and durable surface finishes. Laser-guided metal shaping, precise alignment, and advanced welding methods are more than technical feats; they are instruments for restoring the original geometry and ensuring even stress distribution across repaired zones. The objective is not to recreate a pristine new part but to reestablish the structural integrity that the original design anticipated. When repair teams deliver that outcome, the result is a truck whose performance, safety margin, and long-term durability align with the expectations of end users and regulators. The economic calculus, naturally, remains central. A disciplined rust repair program is not about eliminating cost; it is about distributing risk and securing a vehicle’s operation over a longer horizon. For this reason, many operators adopt a staged approach: tackle the most critical rust first, monitor outcomes, and progress to less urgent areas as the budget and conditions permit. This staggered strategy reduces upfront cash outlays while still delivering meaningful improvements in safety and reliability. It also creates a learning loop: each repair phase yields data about how the vehicle behaves under load, how long protections last, and where future investment would yield the best returns. For those managing fleets, the cumulative gains from long-term planning typically outstrip the initial investment differential between a quick cosmetic fix and a rigorous, professionally executed repair. In a world where fuel economy, uptime, and regulatory compliance are closely watched metrics, the value of rust repair investments becomes a matter of disciplined stewardship. It is about prioritizing areas that affect load bearing and safety, using materials and methods that maximize durability, and maintaining a transparent record of actions taken. It is also about understanding the recurring costs associated with corrosion control and incorporating them into budgets that reflect realistic maintenance needs rather than aspirational repairs. The practical upshot for owners who embrace this philosophy is straightforward: set expectations early, allocate funds for both repair and prevention, and maintain rigorous inspection schedules that catch corrosion before it becomes structural. The payoff comes in quieter, more predictable operation, longer vehicle life, and a stronger standing with buyers who value comprehensive maintenance and documented quality. As a final note, the long-term calculus of rust repair invites owners to connect daily operating realities with strategic financial planning. It requires balancing the desire to minimize immediate expenses with the imperative to protect asset integrity and performance over time. The result is a maintenance culture that recognizes rust repair not as a one-off fix, but as a cornerstone of responsible ownership and prudent fleet management. For readers seeking a concrete starting point in aligning rust repair with broader maintenance goals, a disciplined approach to budgeting for routine truck maintenance provides a useful framework and a reference path Budgeting for Routine Truck Maintenance. Looking beyond internal practices, the broader literature and practitioner experience emphasize the value of integrating preventive coatings, regular inspections after exposure to winter conditions, and careful material choices that resist corrosion over multiple seasons. In practice this adds up to a reproducible cycle of monitoring, treatment, and protection that sustains both the safety and the economic appeal of heavy trucks. For those who want to explore corroborating perspectives on rust repair strategies and long-term maintenance planning, external guidance is available, reflecting industry observations and practical tips that can complement in-house assessments. As you weigh the costs and benefits, remember that the true value of rust repair lies not in the absence of rust, but in the reliability and longevity it preserves across the vehicle’s entire service life. External insights beyond the technical specifics offer useful framing: proactive maintenance and corrosion control can significantly reduce the risk of major structural failure and the accompanying downtime. In this sense, rust repair becomes a strategic, value-creating activity rather than a reactive, isolated expense. This chapter has outlined a philosophy of investment that aligns with responsible fleet stewardship and durable truck performance. It remains to emphasize a key takeaway for decision-makers: plan for durability, not just today’s repairs. When you view rust repair through that lens, the choices you make about materials, methods, preventive measures, and documentation become instruments of long-term value. The result is a fleet that remains safe, compliant, and competitive long after the first patch is applied, with a maintenance narrative that supports continued confidence from drivers, customers, and regulators alike. External resource: https://www.autoblog.com/2024/12/18/truck-rust-repair-tips

Final thoughts

Understanding the multifaceted costs of truck rust repair is essential for maintaining fleet efficiency and safety. Each chapter of this guide has addressed the various aspects of rust repair, from assessing the extent of damage to the critical role of professional evaluations and the long-term implications of repair investments. Implementing a proactive and informed approach will not only safeguard vehicle integrity but also enhance a company’s operational performance, ensuring that rust does not become a liability that hinders business success.