In a world where technology races ahead and the newest diagnostic tools can feel overwhelming, there remains a certain warmth in the memories of simpler times. Picture a family gathered around an old but trusted truck, its engine humming softly as stories of hard work and determination fill the air. For many in the milk-hauling business, this connection runs deeper than nostalgia—it is woven into the very fabric of their lives.

The meticulous process of in-house repairs and custom diagnostics isn’t just a routine; it’s a tradition that spans generations. As fleets like Turnage & Sons continue to deliver nature’s goodness from farm to table, the soul of their operations is rooted in that familial bond and the pride that comes from maintaining their own trucks.

Join us as we explore the indispensable role of DIY maintenance in sustaining a milk-hauling fleet, where every wrench turn echoes the legacy of those who came before us.

At Turnage & Sons, the significance of in-house truck repairs and custom diagnostics runs deep, entwined with the company’s family heritage and values. By choosing to perform most maintenance internally, they sustain the high standards established by previous generations, ensuring that every truck that hits the road reflects the dedication and craftsmanship that defines their legacy. This hands-on approach not only enhances operational efficiency but also fosters strong community relationships, reinforcing their commitment to quality service.

Furthermore, the investment in diagnostic tools means that each member of the Turnage family, particularly the newer generations, gains invaluable skills and insights, facilitating a seamless transfer of knowledge that empowers them to uphold the family’s traditions while adapting to modern challenges. In every wrench turned and every custom repair made, there echoes a commitment to preserving the values that have served their family for five generations, resonating through their mission of delivering organic milk with the utmost reliability and pride.

Data on maintenance practices within trucking fleets reveals distinct trends. Approximately 20% of fleets manage their maintenance entirely in-house, while 46% outsource all maintenance tasks, and 34% adopt a hybrid approach that combines both strategies.

The advantages of in-house maintenance are compelling. First, it grants fleets greater control over their operations, including scheduling and quality of maintenance services, ensuring that these align closely with their specific needs. Additionally, in-house maintenance fosters the development of specialized knowledge among technicians, allowing them to gain expertise specific to the fleet’s vehicles and equipment, which leads to more efficient diagnostics and repairs.

Another significant advantage is the immediate response capability that comes with having an on-site team. This capability minimizes vehicle downtime and enhances overall fleet productivity, allowing companies to maintain a competitive edge.

In contrast, outsourced maintenance can yield cost savings on hiring and training, but lacks the personalized approach and operational control that in-house strategies provide. Ultimately, the choice for fleets often hinges on their size, operational complexity, and resource availability, with many finding synergy in a hybrid approach that leverages the strengths of both in-house and outsourced maintenance.

At Turnage & Sons, the maintenance strategy combines in-house repairs and strategic outsourcing. The family emphasizes in-house maintenance because it allows them to maintain high standards passed down through generations. Robbie Turnage sums up this philosophy:

“We stay on top of our stuff maintenance-wise.”

This proactive attitude helps the Turnage family quickly address issues, ensuring every truck meets their commitment to quality.

However, they also recognize the value of outsourcing at times. External expertise can enhance their operations when necessary. Robbie believes in fixing minor problems before they grow into major issues. This not only saves money but reinforces their reliability.

Teaching younger family members, like Levi, early on is vital. This engagement promotes a culture of hands-on participation, demonstrating their commitment to quality and service. Combining tradition with modern strategies is crucial to their ongoing success in the milk-hauling industry.

| Aspect | In-House Maintenance | Outsourced Maintenance |

|---|---|---|

| Cost | High operational costs due to equipment, facility overhead, technician wages, and training | Cost predictability, potential savings on labor and training |

| Downtime | Risk of increased downtime due to limited after-hours support | Typically lower downtime due to established processes and expert service |

| Control | Greater control over maintenance scheduling, quality, and vehicle history | Loss of control over maintenance processes and scheduling |

| Expertise | Develops specialized knowledge among in-house technicians | Access to specialized expertise and advanced technology |

| Reliability | Reliability tied to internal team skills and resources | Reliability may vary depending on the provider’s performance |

Evidence Section

At Turnage & Sons, the integration of advanced diagnostic tools and software plays a vital role in maintaining the health of their fleet. They utilize a variety of robust systems, such as FleetCross by MOTOR, which streamlines repair workflows through access to extensive OEM-sourced data and detailed diagnostic information. Another significant tool is Preteckt, an AI-driven predictive maintenance solution that continuously monitors real-time sensor data. By detecting potential issues early, this tool saves the company both time and expenses on maintenance and repairs.

Levi Turnage shares a compelling anecdote about a recent troubleshooting experience. During a routine delivery, one of their trucks began displaying unusual symptoms. Instead of panicking, he quickly accessed the Preteckt software, which provided real-time sensor data and predictive insights about potential issues. The diagnostic tool indicated a minor problem with the fuel system, which, if ignored, could lead to significant breakdowns. With this critical information, Levi identified the faulty component within an hour, ordered the necessary parts, and completed the repair just in time for the truck to resume its delivery schedule.

This experience exemplified the effectiveness of the diagnostic tools used by Turnage & Sons, showcasing how these investments empowered them to uphold their commitment to on-time deliveries and customer satisfaction. Levi felt a deep sense of pride in knowing that their proactive approach and the technology at their disposal enabled them to overcome unexpected challenges while maintaining the high standards they set for their fleet.

An image depicting the Turnage family discussing their fleet maintenance practices in a warm gathering, highlighting their family-oriented spirit.

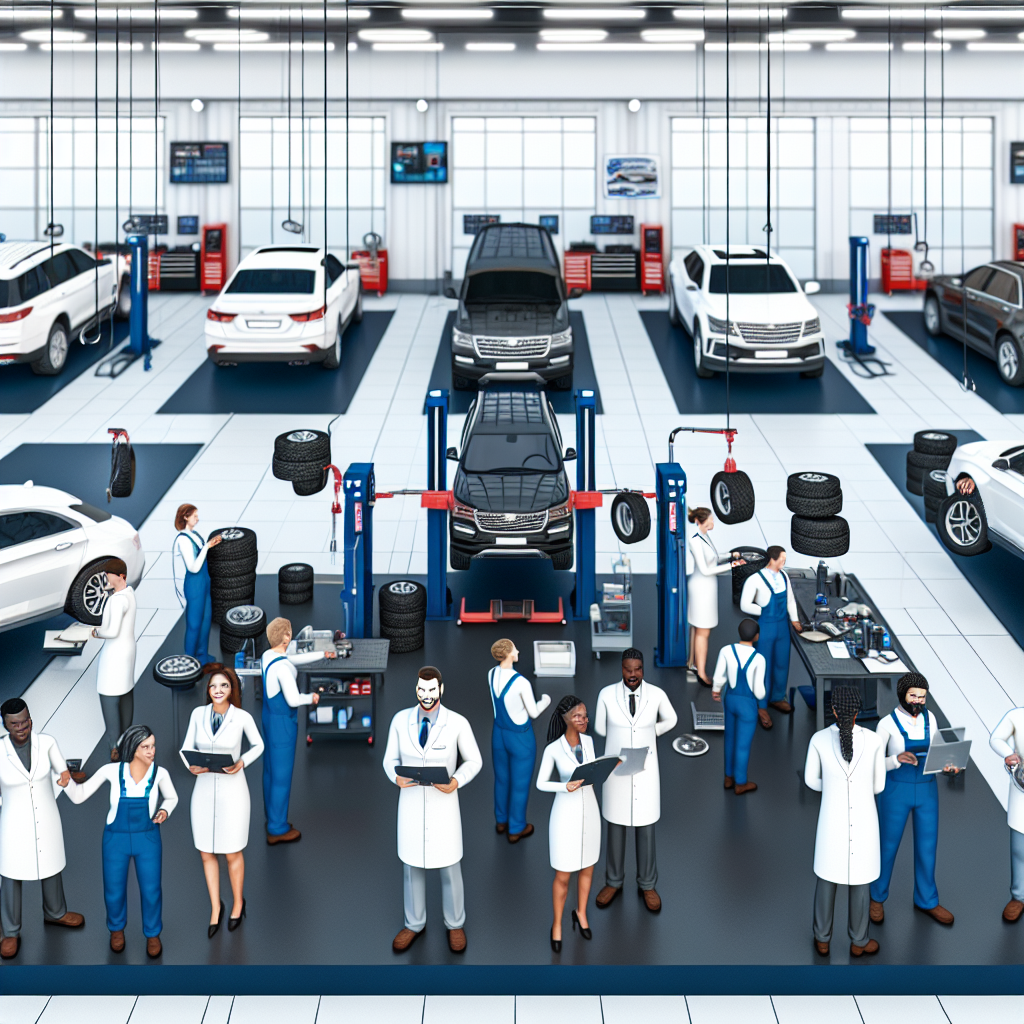

Image of a busy truck maintenance workshop, showcasing technicians working on trucks utilizing modern diagnostic tools and equipment.

An infographic-style representation showing statistics about truck maintenance trends over the past decade, depicting the percentage of fleets using in-house vs outsourced maintenance and the rise of predictive maintenance.

Image of a modern truck maintenance facility equipped with advanced technology, showcasing various diagnostic tools and smart features that assist in repairs.

Diagram illustrating advanced telematics in fleet management, showing how data is captured and analyzed for optimal vehicle performance and maintenance.

Image depicting a fleet of electric trucks with charging stations, emphasizing maintenance strategies for electric vehicles.

Diagram showing the impact of advanced diagnostics on maintenance efficiency for trucking fleets, illustrating a before and after scenario.

Visual representation of fleet maintenance workshops showcasing different maintenance strategies implemented in the industry.

Diagram showing how predictive maintenance impacts cost-savings for a trucking fleet, integrating various metrics and rates.

Illustration of maintenance scheduling software on a computer screen, highlighting key features that improve maintenance planning and execution in truck fleets.

Long-Term Payoff of In-House Maintenance Strategy

The incorporation of an in-house maintenance strategy within trucking fleets, such as those employed by Turnage & Sons, presents a wealth of long-term benefits that extend beyond immediate cost savings. One significant payoff is the notable increase in productivity. Research indicates that more than a third of fleets report productivity enhancements averaging 14% when leveraging internal maintenance practices. This productivity boost translates into faster turnaround times and improved customer satisfaction, vital in the competitive milk-hauling industry.

Moreover, choosing to perform maintenance in-house can lead to striking cost reductions. Regular preventive maintenance has been shown to slash repair expenses by up to 80% relative to reactive approaches. Simple practices, like biweekly engine fluid checks, have demonstrated their effectiveness in avoiding severe engine failures that could incur costs ranging between $11,000 to $22,000 for repairs. Additionally, keeping brakes well-maintained can halve replacement costs, providing further financial relief to businesses.

Incorporating predictive maintenance technologies further amplifies these advantages. Utilizing AI-driven platforms can yield up to a 25% increase in vehicle uptime and help companies save around $2,000 annually per vehicle by addressing issues before they escalate. This proactive approach not only boosts operational efficiency but enhances the longevity of the fleet, making it a wise investment.

Industry experts echo these sentiments, with Norman Thomas, a fleet business consultant from Uptake, stating that predictive maintenance analytics can dramatically improve driver experience by identifying and prioritizing issues early. Such informed strategies lead to increased reliability on the road, adding another layer of assurance for both employers and drivers.

In summary, the long-term advantages of an in-house maintenance strategy are evident. Cost efficiency, enhanced productivity, and an emphasis on proactive care ensure that fleets not only thrive operationally but also build a resilient foundation by nurturing specialized knowledge and skills. Engaging in consistent maintenance fosters a culture of dedication and proficiency that can resonate through generations, making it not only a strategy for profit but a legacy of excellence in the industry.

Family History in Milk-Hauling

The Turnage family has a deep-rooted legacy in the milk-hauling business, spanning five generations. Their commitment to in-house truck maintenance is a core aspect of their operation, reflecting a tradition of hard work and hands-on dedication. This approach not only enhances the longevity of their fleet but also instills pride within the family, as members participate in vehicle upkeep and repairs.

The values of craftsmanship, reliability, and family-centered work ethic have been passed down, shaping the culture of Turnage & Sons. Each generation contributes to the mechanics of trucking, ensuring that the trucks are maintained to high standards, just as their ancestors did.

An image depicting the Turnage family discussing their fleet maintenance practices in a warm gathering, highlighting their family-oriented spirit.

In conclusion, the commitment to in-house repairs and diagnostics is a defining characteristic of successful milk-hauling fleets like Turnage & Sons. This family-owned operation not only exemplifies a rich legacy of craftsmanship and determination but also showcases the tangible benefits of a hands-on approach to maintenance. By performing repairs internally, they gain exceptional control over their processes, ensuring high standards are met with each service. Moreover, investing in custom diagnostics and robust tools enhances their operational efficiency, ultimately leading to improved productivity and significant cost savings. The emphasis on developing specialized knowledge within the family empowers future generations to uphold their traditions while navigating modern challenges.

In reflecting on their journey, Robbie Turnage recalls stories from his childhood, reminiscing about the days spent with his grandfather, Q.D. Turnage, who began transporting milk in labor-intensive 10-gallon cans. Robbie shares, “I was usually with her on the weekends or during the summertime pulling hoses.” This connection between generations is crucial for the Turnages, as Levi, the fifth generation, describes his early days: “I was just born into it. I wouldn’t change a single thing about it.”

Through dedicated maintenance efforts, Turnage & Sons not only preserves their esteemed heritage but also continues to deliver reliable service that reflects the pride and hard work of their predecessors. Their story serves as an inspiring reminder of the value and effectiveness of in-house maintenance strategies within the milk-hauling industry, ensuring both operational success and familial legacy endure for years to come.

Key Insights into In-House Maintenance

- In-House vs. Outsourced Maintenance: A comprehensive understanding reveals that 20% of trucking fleets manage maintenance entirely in-house, while 46% outsource. The remaining 34% combine both approaches, highlighting the diversity in operational strategies.

- Advantages of In-House Maintenance:

- Control: In-house maintenance offers greater oversight on quality and scheduling.

- Expertise Development: Internal teams cultivate specialized knowledge tailored to the fleet’s unique needs.

- Immediate Response: Proximity to the vehicles enables swift action, minimizing downtime effectively.

- Challenges of Outsourced Maintenance:

- Less Control: Outsourced services may lead to inconsistent quality and scheduling pitfalls.

- Potential Cost Savings: While outsourcing may save on labor costs, it often lacks the personalized touch and accountability of in-house strategies.

Factors Influencing Maintenance Decisions

- Fleet Size: Smaller fleets may benefit more from in-house solutions, while larger fleets often have more resources to manage outsourcing effectively.

- Operational Complexity: Companies with complex operations may need more tailored solutions that in-house maintenance provides.

- Resource Availability: The decision varies significantly based on the resources available—both human and financial.

- Hybrid Solutions: Many companies find success by employing a hybrid maintenance strategy that leverages the strengths of both in-house and outsourced methods.

These key insights provide a framework for understanding the dynamics of maintenance strategies in trucking fleets, particularly for those like Turnage & Sons that emphasize in-house solutions.

Outbound Links for SEO

In the realm of SEO, leveraging long-tail keywords is vital for driving targeted traffic to your site. Here are some reputable sources that delve into long-tail keywords related to sustainable truck maintenance practices and dairy logistics innovations:

- Greener Trucks & Trailers: Steps to Take Toward Sustainable Operations (MICHELIN Connected Fleet) – This article emphasizes the significance of regular maintenance and tire management in achieving sustainable truck operations, detailing strategies to optimize efficiency.

- Transformation of the Dairy Supply Chain Through Artificial Intelligence: A Systematic Review (MDPI) – A comprehensive review that explores how AI enhances efficiency, quality control, and sustainability in dairy logistics.

- From A to Z: Addressing Transportation Challenges in Dairy Farming (Dairy Global) – Discusses innovative technologies in dairy logistics that can improve efficiency and sustainability.

- Sustainable Maintenance (WorkTrek) – Outlines strategies for improving sustainable maintenance practices, providing insights on enhancing energy efficiency and equipment longevity.

- Sustainable Practices for US Truck Fleet Management (FleetRabbit) – Focuses on how sustainable practices such as route optimization and load efficiency can improve delivery performance and achieve sustainability gains.

Utilizing these resources in your SEO strategy can aid in capturing a targeted audience interested in sustainable practices within trucking and dairy logistics, positioning your business effectively in a competitive landscape.