The operational efficiency of your fleet hinges on the reliability of your medium-duty trucks. As a fleet manager or operator in the transportation or construction sector, understanding where to find quality truck repair services is pivotal. This guide will equip you with essential knowledge on local resources for repairs, the technologies they utilize for diagnostics, standards for selecting repair providers, and the benefits of mobile repair services. In the chapters ahead, we will explore these aspects in depth, ensuring you can maintain your fleet’s peak productivity with minimal downtime.

null

null

Where to Find Medium-Duty Truck Repair: From Specialist Shops to On‑Site Services

When a medium-duty truck falters on the road or a routine maintenance alert blinks in the fleet dashboard, the question isn’t just what’s wrong, but where to get it fixed fast and right. The market for medium-duty truck repair is broad by design, reflecting the diverse duties these vehicles perform—from urban delivery routes and construction site support to regional tanker runs and municipal service work. You can find repair services in three broad settings: independent or specialized automotive shops that focus on commercial fleets, dealer service departments tied to a specific manufacturer or brand ecosystem, and mobile repair providers who bring skill and equipment directly to a truck’s location. Each channel has its strengths, and understanding how they differ helps you match the repair needs to the right facility, minimizing downtime and ensuring trucks return to service with the right repairs, not just a temporary fix. In practice, most fleet managers and owner-operators build a small, trusted network rather than rely on a single shop, so they can cover scheduling gaps, on-site emergency calls, and seasonal maintenance cycles with reliability and speed. The core idea is simple: you want access to the right tools, the right technicians, and the right practices, no matter where the repair happens.

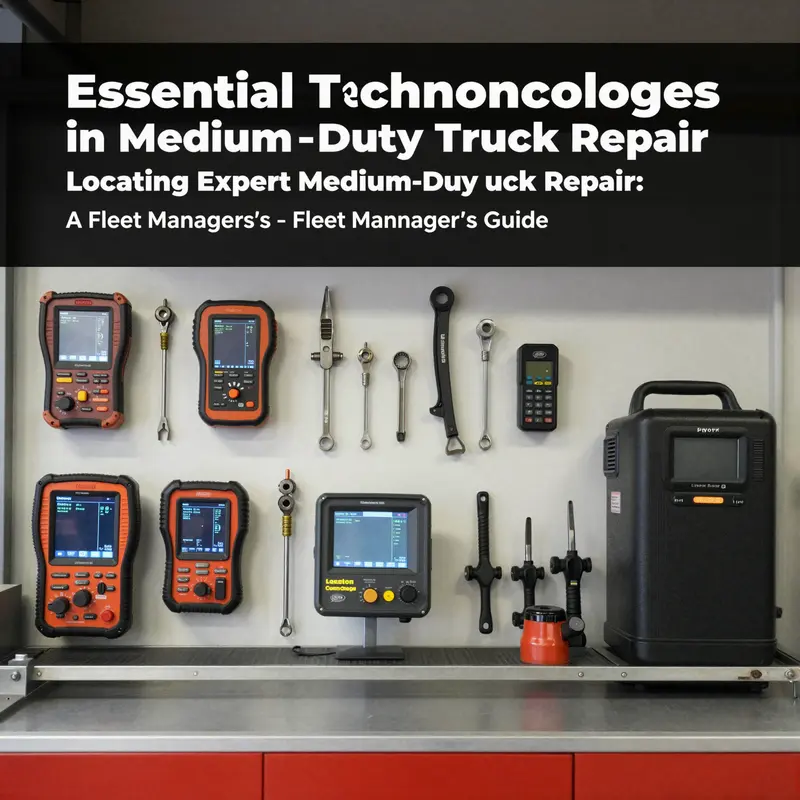

Specialized repair shops, for their part, sit at the intersection of technician expertise and the breadth of equipment necessary for medium-duty applications. These shops typically maintain a robust diagnostic suite that interfaces with the truck’s onboard computer systems, commonly through advanced scan tools and diagnostic software. Such tools read fault codes, monitor real-time performance, and support critical tasks like reprogramming engine and transmission settings when warranted by the fault history. In modern fleets, where emissions compliance, fuel efficiency, and reliability hinge on precise control of engine management and exhaust aftertreatment, a shop’s digital capabilities are as important as its mechanical hand tools. The kind of equipment you find in these shops often includes high-precision torque wrenches with digital readouts, laser alignment devices, digital calipers and micrometers for wear measurement, and a full suite of brake service stations and wheel-end equipment. These capabilities aren’t cosmetic; they directly translate into the technician’s ability to return a vehicle to service with components torqued to exact specifications and alignments that protect tire life and handling performance.

Dealership service departments provide a different value proposition. They operate within the framework of manufacturer standards and often benefit from direct access to OEM-specific software, updates, and best-practice repair procedures. For fleets that rely on a single brand’s components or who are enrolled in formal manufacturer programs, this route can offer a higher assurance of compatibility and long-term support. Dealers tend to be particularly strong when the work touches critical drivetrain or emissions-control systems, where the latest service bulletins and software calibrations can have a meaningful impact on performance and compliance. The trade-off sometimes comes in scheduling flexibility; dealer bays can be busier, especially in regions with dense commercial traffic or during fleet maintenance windows. Still, the advantage of manufacturer-aligned training, factory-approved repair procedures, and access to OEM diagnostic software can be decisive for fleets that must maintain high uptime.

Mobile repair providers bring the same diagnostic rigor and mechanical capability as the shop floor, but with the benefit of proximity and speed. A mobile team can diagnose a vehicle in the field, perform select repairs on-site, and tow or haul the truck only if extensive work is required. For fleets that operate across large geographic areas or within tight downtime windows, mobile service reduces the time trucks spend out of service and minimizes the logistics of moving a vehicle. The technicians on these missions carry a compressed toolkit designed for on-site use, including portable scanners, hydraulic jacks, and a curated set of common wear parts. When evaluating mobile options, it’s useful to confirm their coverage area, response time, and whether they can perform critical tasks like brake service, basic engine diagnostics, transmission checks, or cooling system work. The trend toward mobile repair also aligns with a broader shift toward minimizing downtime and keeping fleets moving, a shift that is evident in many regional fleets and independent operators alike.

No matter the service channel, the human element remains central. Certified technicians, supported by a carefully maintained inventory of parts and a clean, safety-conscious work environment, are the fulcrum of successful medium-duty repair. Certifications such as ASE recognition signal a technician’s adherence to professional standards, and many shops bolster credibility with manufacturer-trained technicians who understand the precise tolerances and service procedures for common engine families and transmission configurations found in medium-duty applications. In practice, customers often gauge reliability not only by credentials, but by the shop’s approach to safety and process. The best facilities integrate formal safety protocols around lifting and jacking operations, use documented work instructions, and maintain a culture of ongoing training. These practices help prevent common failure modes and accidents that can occur when heavy components are serviced without meticulous procedure.

The diagnostic and repair landscape is increasingly data-driven. Modern medium-duty trucks, especially those used in regional service or urban delivery roles, run complex networks of sensors and control modules that govern engines, transmissions, brakes, and emissions systems. A shop’s capability to read and interpret fault data determines how quickly they can pin down root causes and plan the fix. Look for facilities that pair robust diagnostic hardware with software subscriptions and ongoing technician training. This combination supports not only fault isolation but also proactive maintenance planning. The ability to pull vehicle history, compare live performance data across a fleet, and spot patterns—such as recurring issues with a particular engine variant or a date-coded service bulletin—helps fleets move from reactive repairs to structured maintenance programs that improve uptime and reduce total cost of ownership.

Beyond the diagnostic bay, the physical workshop environment matters. A well-equipped medium-duty facility houses lifts and jacks rated for higher weight classes, frame straightening capabilities, and dedicated brake service stations. Wheel services—alignment and balancing—play a crucial role in tire longevity and road handling, which in turn affects fuel efficiency and safety. A calm, orderly shop with proper ventilation, adequate lighting, and clear safety signage signals a mature operation that prioritizes worker safety and reliable turnarounds. The physical setup supports efficient workflow, enabling technicians to move parts, tools, and components through a predictable sequence rather than chasing missing hardware or misaligned gears. In this context, learning a shop’s workflow matters as much as its tool inventory. A smooth process reduces the risk of mis-torqued fasteners, misaligned axles, or timing discrepancies in engine control modules.

The topic of safety is especially salient for medium-duty repairs that occur on rolling freight, municipal services, or construction support vehicles. In colder regions where winter conditions test traction and braking, fleet operators may adopt proactive safety measures such as equipping trucks with more capable tires on all axles and implementing winter maintenance plans that address salt exposure, corrosion, and brake wear. The literature and industry guidance increasingly emphasize proactive safety and maintenance as a way to reduce downtime and accident rates. Shops that communicate these standards—through practical guidance, transparent maintenance checklists, and clear post-repair documentation—demonstrate a commitment to reliability that goes beyond the immediate repair job.

For those responsible for budgeting and planning, the decision about where to repair a medium-duty truck hinges on more than price. It hinges on uptime, predictability, and the long-tail value of a repair, which includes the likelihood of future issues arising from a given fault or repair method. A reputable shop or service network typically offers a balanced mix of diagnostic depth, mechanical capability, and logistical flexibility. Fleet operators often benefit from developing a small panel of trusted partners across the three channels—independent shops, dealer service centers, and mobile providers—so they always have a viable option when a breakdown occurs or a scheduled maintenance window arrives. This approach minimizes downtime by matching the repair scenario with the most efficient, safe, and compatible service channel.

As a practical step in locating the right partner, begin with a broad survey of options in your area using online directories and fleet-focused networks. Then, verify a few core competencies: are technicians ASE-certified or otherwise credentialed? Does the facility maintain exchange programs with manufacturers or have access to OEM service bulletins and software updates? Is there visible evidence of a structured safety program that aligns with OSHA guidelines, including proper lift operation and fall protection? And does the shop show a track record of reliability and transparency through customer reviews and clear warranties on repairs? In many cases, the most durable solution is a hybrid approach: a primary shop for routine diagnostics and major repairs, a secondary shop for quick-turnaround maintenance, and a mobile service provider dispatched for urgent calls when travel time or shelter-in-place constraints make a shop visit impractical.

Among the anchors of this ecosystem is the ability to access high-quality diagnostic data without unnecessary delay. The use of industry-standard tools, such as advanced truck scanners and integrated diagnostic software, enables technicians to interrogate engine management, transmission control, braking systems, and emissions components with precision. This digital backbone is what allows a repair to be correctly scoped, parts to be ordered ahead of time, and technician time to be framed with a clear plan. It also supports validation testing after the repair, confirming that fault codes have cleared and that sensor readings return to expected ranges. When a shop demonstrates command of these tools and couples them with careful measurement and alignment practices, you gain confidence that the work completed will hold up under the demands of urban routes, long-haul detours, or severe weather cycles.

To summarize the practical landscape: you can find medium-duty truck repair at specialized shops that marry mechanical skill with digital diagnostics, at dealer service departments that bring OEM alignment and software support, and at mobile repair providers who minimize downtime by arriving on site with a ready-to-work toolkit. The common thread across this spectrum is a strong emphasis on safety, precision, and reliability. A smart approach for fleets and operators is to cultivate a network that spans these channels, supported by a clear set of criteria for selecting partners—credentialing, safety culture, diagnostic capability, equipment readiness, and a history of dependable service. In this way, the search for repair becomes less about a single location and more about assembling a resilient repair network that keeps medium-duty trucks on the road when they are needed most. For those who want to explore a concrete example of an established in-house maintenance approach, see the dedicated resource on Turnage-Sons in-house truck maintenance, which offers a window into how on-site maintenance programs are structured and sustained, illustrating a practical model for fleet teams seeking to reduce downtime with on-site expertise. turnage-sons-in-house-truck-maintenance

For further guidance on the tools and standards that underpin modern medium-duty repair, it helps to consult external industry resources that outline diagnostic ecosystems and the maintenance technologies that shops rely on. One widely used reference is the diagnostic and service ecosystem developed by major engine and component manufacturers, which reinforces the importance of dealer networks and certified technicians in maintaining fleet reliability. These resources provide context for how shops access the latest software updates, calibrations, and alignment procedures that keep engines compliant and performant across changing regulatory and operational environments. The overarching message is clear: the right repair partner is defined not only by what is fixed, but by how data-informed the repair process is, how precisely parts and fasteners are installed, and how safety and ergonomics are integrated into every step of the workflow.

In the end, the search for medium-duty truck repair is a hunt for networks that understand the real-world demands of fleets operating across urban corridors, rural routes, and everything in between. It is a hunt for partners who can translate fault codes into action without forcing a truck into unnecessary downtime, who can align parts and torque with manufacturer specifications, and who can stand behind a repair with clear warranty terms and transparent communication. This is the backbone of uptime-driven maintenance: a well-chosen mix of shops, dealers, and on-site teams that together form a resilient repair ecosystem for medium-duty fleets. External resources and official dealer networks can be invaluable starting points for mapping that ecosystem and identifying eligible providers in your area. For the broader context of diagnostic and repair technologies that empower these providers, see the authoritative technical landscape maintained by the engine and component manufacturers. External resource: https://www.cummins.com

Trust, Certification, and Craft: Finding the Right Medium-Duty Truck Repair Partner

Choosing where to repair a medium-duty truck is more than finding a place that can swap parts. It is about minimizing downtime, protecting uptime, and ensuring safety on the road. The options range from specialized independent repair shops to dealer service centers and on-site mobile teams. Across all these options, three threads run through a high-performing relationship: a solid footing in recognized certifications, a record of reliable, transparent service, and the technical breadth to handle engines, transmissions, brakes, axles, and the body. The best providers blend these strengths with the capacity to diagnose precisely and to communicate clearly about what a fix will cost and how long it will take.

Certifications form the backbone of trust. The acknowledged standard for technicians working on medium- and heavy-duty trucks is the ASE Master Technician certification in Medium/Heavy Duty Truck. This credential signals that a technician has passed rigorous exams that cover engine performance, electrical systems, brakes, and drivetrain components, among others. It is not the only credential in play, but it remains a reliable signal that the shop employs staff who have proved their knowledge and their ability to apply it under pressure. When this certification is paired with ongoing manufacturer-specific training, the shop signals intent to stay current with evolving diagnostics, safety standards, and warranty expectations. While the exact badge may vary by program, the underlying discipline is the same: a technician who can read the engine’s heartbeat, interpret the electronics that control braking and transmission, and translate the results into actionable repairs.

Beyond universal certs, many facilities pursue manufacturer-oriented training that teaches the quirks of a specific make or family of vehicles. These training tracks improve the shop’s capacity for diagnostics and warranty work because they map out the software interfaces, service bulletins, and diagnostic paths that technicians will encounter in the field. In practice, this reduces guesswork during a repair and helps avoid mismatches between parts, software updates, and hardware. For a fleet that relies on predictable maintenance windows, having techs with this level of specialization matters as much as the core ASE credentials. The result is a repair partner that can handle a wide range of tasks—from engine performance diagnostics to complex transmission troubleshooting—without forcing you to chase specialists from one place to another.

Selecting a shop means more than scanning for a credential wall. It requires a practical check of how those certifications translate into real-world outcomes. Start by asking to see current certificates and, if possible, get names of the technicians who will work on your truck. Verify the licenses and certifications through recognized bodies, and when in doubt, contact the certifying agency to confirm status. The ASE website provides a clear path to verify Master Technician credentials and offers guidance on what the certification covers. A credible shop will also encourage you to review their staff’s ongoing education, not just their current cards. This demonstrates a culture of learning, which is essential when new diagnostic software or updated emissions controls enter the field. If a shop’s materials emphasize speed over accuracy, or if they downplay the importance of certification in favor of quick fixes, that is a red flag.

Equally important are the opinions of those who have lived with a repair shop’s work. Independent customer reviews on platforms like Google, Yelp, and the BBB offer real-world glimpses into service quality, transparency, turnaround time, and how a provider handles unexpected hiccups. Look for patterns: consistent communication, a straightforward explanation of what is wrong, an itemized estimate that aligns with the final bill, and a willingness to discuss options when a repair reveals a bigger issue. Honesty and professionalism should thread through every interaction. A shop that takes time to set expectations, explains the rationale behind recommended repairs, and provides a written plan for preventive maintenance earns trust even before the first invoice is paid. Conversely, reviews that describe vague estimates, unexplained charges, or repeated delays can indicate a shop that struggles with scheduling, parts availability, or customer communication.

To translate certification and reputation into a smooth repair experience, think through the practical flow of a typical job. A competent shop will begin with a diagnostic approach that balances speed and accuracy. They will isolate the symptom, confirm with tests, and then present a detailed work plan. Ask for an itemized estimate that lists labor, parts, and any additional maintenance that is prudent given the truck’s duty cycle. Transparency is not just a price matter; it is a signal of accountability. A reliable partner will show you a timeline and will keep you updated if the scope changes. For fleets, that transparency matters more than the initial price tag because a minor miscommunication can cascade into hours of downtime. A well-run shop will also discuss warranty terms on repairs and will outline how long the diagnostics and service guarantees last, so you know what coverage you have if a replacement part fails or if a repair does not deliver the expected result.

Equipment and capability also matter, and the best shops historically invest in tools that enable precise, repeatable results. In a modern medium-duty environment, technicians rely on industry-standard diagnostic scanners to interrogate engines, transmissions, and emissions systems. They use torque multipliers to ensure fasteners are secured to spec, cylinder hones for restoring piston rings, and differential bearing pullers for axle service. This catalog of hardware is not a flashy display; it is the hands-on infrastructure that makes a repair durable and repeatable. A shop with such tools is more likely to handle serious repairs in-house, which reduces wait times and limits the need for multiple handoffs between locations. It also means that the repair center can perform preventive actions during a single visit—like timing belt or chain checks, fluid analysis, and electrical system tests—without forcing you to cycle through a network of vendors.

Downtime is the silent cost of engine trouble. Some providers have built value by offering on-site mobile repair teams that come to a fleet’s base or a job site, bringing the diagnostic know-how and a subset of repair capabilities directly to your location. For many operators, this convenience translates into reduced idle time, especially when large blocks of work must occur after hours or during tight delivery windows. Mobile services can complement a fixed-location shop by handling minor repairs, initial diagnostics, tire service, or brake adjustments on the road, saving the more complex disassembly for a dedicated shop visit. When evaluating mobile options, confirm the technician’s scope of work, the typical response time, and the reliability of parts supply on-site. A strong mobile arm expands your network’s reach and gives you a reliable fallback plan during peak seasons or when your own maintenance staff is stretched thin.

Choosing a repair partner is ultimately about aligning capabilities with your fleet’s needs. A dependable provider demonstrates consistency across several dimensions: clear communication, documented certifications, transparent pricing, productive scheduling, and the technical breadth to handle both routine maintenance and unexpected failures. They will be ready to talk through a maintenance plan that fits your operation’s cycle and duty profile—from urban delivery to regional hauling—and will help you build a preventive program that reduces the likelihood of repeated breakdowns. Having a trusted partner also supports your broader risk management strategy, including the ability to maintain service histories, track vehicle uptime, and plan capital expenditures around predictable repair costs. The best relationships grow from a shared understanding of goals: maximize uptime, extend asset life, and keep drivers safe and confident behind the wheel.

To explore how a repair partner builds value into ongoing service and to see a practical example of how information about a shop’s process is shared online, you can visit the Master Truck Repair blog. This resource offers insights into maintenance planning, budgeting for routine care, and emergency repair fund considerations that fleet operators commonly grapple with. It offers a grounded perspective on how to structure conversations with shops, how to compare bids without compromising quality, and how to document service history so that every technician who touches a truck can pick up where the last left off. The blog content reinforces the idea that choosing a repair provider is not a one-off transaction but the start of a long-term working relationship built on trust and measurable performance.

Finally, the standard you expect doesn’t end at the shop door. The industry recognizes a framework of certification and best practices that underwrite the integrity of repairs, diagnostics, and maintenance planning. The ASE guidelines, and related programs that underpin technician training, provide a defensible benchmark for what constitutes skilled work on medium-duty fleets. When a shop points to these standards and demonstrates ongoing adherence, you gain assurance that the work will be performed by capable hands with a commitment to safety and reliability. For fleet operators who must balance service quality with budget realities, this alignment between certification, transparent review, and practical capability forms the foundation of a trustworthy repair ecosystem. In practice, it means you can rely on a partner that respects your uptime goals, who explains the work in plain terms, and who backs their repairs with a warranty and a clear path for future maintenance.

External resource: ASE Standards.

Finding Medium-Duty Truck Repair: A Roadmap Through Shops, Dealerships, and On‑Site Teams

When a medium-duty truck needs service, the question is rarely whether to repair but where to repair. The path to reliable maintenance and swift diagnostics weaves through three primary channels: specialized independent repair shops, dealership service departments, and mobile repair teams that come to the customer. Each option carries its own strengths, and the best choice often hinges on the nature of the job, the urgency of downtime, and the configuration of the fleet. A thoughtful approach to locating trusted providers begins with understanding what modern medium-duty repair entails and how shops differentiate themselves beyond price or a shiny set of tools.

In many regions, specialty shops that focus on medium- and heavy-duty commercial vehicles form the backbone of dependable maintenance. These facilities are typically stocked with industry-standard diagnostic equipment and heavy-duty hand tools that align with the demands of engines, transmissions, brakes, axles, and the axial assemblies that bind a fleet’s performance to uptime. The average repair plan in this space blends preventive maintenance with rigorous diagnostics. Technicians are trained to interpret a wide array of fault codes, monitor emissions systems, and assess driveline wear without veering into speculative repairs. What sets these shops apart is not just their equipment, but their workflow: a diagnostic-to-repair pipeline that minimizes back-and-forth, with technicians who understand how a single fault can cascade into multiple subsystems failing in concert.

As fleets expand their horizons, many repair facilities extend their capabilities through formal partnerships and certifications. Some shops align with major manufacturers, while others concentrate on commercial-vehicle service with ASE-certified technicians. The alliance with manufacturers, in particular, signals access to device-specific procedures and recalibration steps that ensure repairs restore original performance levels. Even without naming brands, the underlying advantage is the same: a tested, standards-driven process that reduces misdiagnosis and increases the likelihood of a first-time fix. This is especially important when the repair touches critical components such as the engine or the braking system, where precision saves downtime and prevents costlier failures down the line.

Dealership service departments occupy a unique niche within this ecosystem. They bring the assurance of factory-trained technicians and access to manufacturer-backed service bulletins and software updates. For fleets that rely on precise engine calibration or transmission software, dealerships can offer a level of diagnostic depth that is difficult to replicate in a standalone shop. The price tag may be higher, but the trade-off is a longer horizon of guaranteed compatibility with the vehicle’s original configurations and warranties that remain intact through the service cycle. In many cases, dealerships also provide a coordinated maintenance schedule, fleet-specific service plans, and a more transparent parts supply chain—benefits that translate into predictable downtime planning and clearer budgeting.

Then there are on-site mobile repair services, a category that has grown in response to the logistics pressures of modern operations. Mobile units bring a surprising breadth of capability directly to the customer’s location. They operate from specialized trucks that resemble compact workshops on wheels, often equipped with diagnostic computers, hydraulic tools, and secure storage for spare parts. The advantage here is straightforward: the vehicle doesn’t leave the site. For fleets running high-utilization routes, the ability to inspect, repair, and test a vehicle within hours, or even minutes, dramatically reduces downtime and preserves route continuity. Mobile units can cover everything from routine maintenance—oil changes, filter replacements, and brake pad checks—to more complex tasks like drivetrain adjustments or minor electrical fixes. The scope of work is, in essence, dictated by what the mobile shop carries in its compartments and how the crew’s skill set translates to on-site constraints.

Inside the mobile workshop, certain capabilities have become common-in-market signals of value. One notable component is the presence of an inside mobile tyre changer for trucks. This alloy of precision and speed—often automated or semi-automated—allows technicians to break beads and mount tires with a level of accuracy that minimizes tire damage and speed-related risks. It also harmonizes with the broader objective of mobile service: to widen the range of maintenance tasks that can be completed without returning the vehicle to a fixed garage. For fleets with mixed tire sizes and frequent tire service needs, such equipment turns a potentially disruptive downtime event into a routine maintenance operation performed on site.

Beyond tire services, mobile workshops frequently feature weatherproof, enclosed compartments. These spaces protect tools, parts, and delicate diagnostics from the elements while keeping everything organized and secure. A modular design supports a variety of wheelbases and roof heights, which translates into better maneuverability in urban environments and tighter job sites. The practical effect is straightforward: technicians can carry an expanded toolbox without compromising safety or efficiency. When the job requires more than basic preventive maintenance, a well-equipped mobile unit can stabilize the situation, performing diagnostic tests, component replacements, and surface-level repairs with a workflow that mirrors a fixed shop’s capabilities while preserving the vehicle’s place on the road.

A core objective across all channels is reliable diagnostics. In practice, that means devices that can read and interpret fault codes, monitor engine and emissions performance, and verify that post-repair the system behaves as intended. The diagnostic process is only as good as the software and the technician wielding it, which underscores the value of choosing a service partner with access to robust diagnostic tools and up-to-date programming interfaces. Real-time diagnostics not only shorten repair cycles but also help prevent minor issues from evolving into critical failures. The best providers combine software-driven fault isolation with hands-on mechanical checks, ensuring that a repair is both technically sound and practically durable.

From a fleet-management perspective, the decision about where to repair should be anchored in downtime risk, cost predictability, and the location of the vehicle when service is needed. On-site mobile repair offers maximal uptime resilience for time-sensitive operations, while dealership and specialty-shop routes often yield the deepest diagnostic insights and potential for manufacturer-approved fixes when the problem is systemic or complex. Independent repair shops, meanwhile, can strike a balance by delivering cost-conscious, flexible service with a proven track record in the local market. The key is to align the service approach to the fleet’s operating profile: the routes, the maintenance cadence, the criticality of each vehicle to the network, and the desired level of documentation for compliance and budgeting.

Finding the right partner also hinges on the credibility of the technicians. Certifications, such as those awarded by automotive associations, signal a baseline of competence and adherence to industry standards. In the realm of heavy- and medium-duty work, certifications coupled with manufacturer-aligned training indicate a technician who understands the particularities of the fleet’s equipment. Customer reviews, fleet referrals, and professional networks matter just as much as the tools in the shop bay. A repair provider that routinely works with fleets of similar size and with a comparable service schedule is more likely to deliver consistent performance in both diagnostics and turnarounds. In practice, verifications come through a combination of online reviews, direct inquiries about technician qualifications, and a request for a transparent service plan that outlines the diagnostic steps, anticipated parts, and the projected downtime.

Locating a reputable provider is rarely a single-step decision. For many operators, it starts with a practical search on widely used online directories and map services that reveal nearby options and help compare proximity, hours, and basic service descriptions. A smart search extends into trusted industry networks—fleet-management contacts, local trucking associations, or maintenance partnerships—that can provide recommendations grounded in firsthand experience. The aim is not just to discover a place to fix the vehicle but to identify a partner that can support preventive maintenance programs, offer consistent service quality, and respond quickly when emergencies arise. In this sense, the repair decision becomes part of a broader strategy to minimize the operational risk associated with vehicle downtime and to preserve the reliability of the fleet’s delivery commitments.

To illustrate how this ecosystem looks in practice, imagine a medium-duty fleet that operates a mixed route profile with quick turnarounds on urban corridors and periodic long-haul legs. When a fault appears in the engine management system, the fleet manager might first contact a local specialist shop known for fast diagnostics and a transparent work order process. If the problem is straightforward, a technician might perform a diagnostic scan, replace a sensor, and re-test the system in a matter of hours. If the fault is more systemic—say, an emissions-related concern that requires software recalibration or a driveline update—the same shop could coordinate with a manufacturer-certified program to ensure the repair aligns with factory specifications. In parallel, if the vehicle is in a city center corridor or at a distribution hub, a mobile team could be dispatched to perform a rapid on-site inspection and handle tasks that don’t demand heavy lifting or a full workshop bay.

This integrated approach—combining the reach of mobile service with the depth of fixed facilities and the assurance of manufacturer-backed procedures—often yields the most resilient maintenance strategy. It allows fleet operators to flexibly allocate resources, minimize downtime, and ensure that repairs are performed to the standard that preserves warranty protections and long-term resale value. The process also benefits from clear documentation: a repair history that captures the diagnostic steps, parts used, and verification tests after completion. Such records support compliance with regulatory requirements and help fleet managers refine maintenance plans over time, making future interventions more targeted and efficient.

For readers seeking a practical starting point in their local area, one useful step is to identify a few nearby options that fit the fleet’s scale and schedule. Start by checking online directories for nearby shops and dealerships, then narrow the list by confirming certifications and requesting references from other fleets with similar operations. When possible, arrange a short consultation to discuss how the provider handles diagnostic workflows, warranty terms, and after-hours support. A transparent service agreement that outlines response times, diagnostic timelines, and a warranty window on parts and labor provides a foundation of trust and reduces the risk of ambiguous outcomes should issues recur.

To keep the momentum up, consider engaging with a content-rich source that routinely addresses the realities of truck maintenance and repair. If you want to explore more about fleet maintenance planning, visit the Master Truck Repair blog for practical guidance and fleet-management insights. This resource can offer perspectives on budgeting for routine repairs, building an emergency repair fund, and optimizing maintenance cycles for small fleets, all of which reinforce how a well-chosen repair partner fits into a broader operational strategy. Master Truck Repair blog

In closing, the question of where to find medium-duty truck repair does not have a single universal answer. It depends on the fleet’s needs, the time constraints, and the local ecosystem of service providers. The strongest approach is to cultivate relationships with three complementary channels: a trusted specialist shop for deep diagnostics and complex repairs; a dealership service department for factory-aligned maintenance and software updates when required; and a mobile repair team for on-site service that can preserve uptime during peak operations. With the right combination, a fleet can navigate the repair landscape with confidence, ensuring that every vehicle returns to the road swiftly and safely. The result is not just a repaired truck but a more reliable, predictable operation that supports on-time deliveries and longer asset life.

External resources can further inform this journey. A leading diagnostic tool provider maintains a comprehensive catalog of service procedures, software interfaces, and training resources that help technicians stay current with evolving engine and emissions technologies. While the exact tools used may vary by location, the principle remains constant: diagnostics done well saves downtime, and repairs done to standard preserve performance over the long haul. For additional context on diagnostics and service approaches, refer to the external resource at the organization’s official site: https://www.cummins.com.

Final thoughts

In the realm of medium-duty truck operation, timely and effective repair services are crucial for maintaining productivity and minimizing costs. By understanding where to locate reliable repair providers and the latest technologies they employ, fleet managers, construction operators, and logistics service providers can make informed decisions. Emphasizing the importance of certifications and customer feedback ensures you work with trusted professionals. Mobile repair services further enhance efficiency, allowing for quick fixes without compromising operations. Keep these insights in mind to support your fleet’s reliability and performance on the road.